© 2025

All rights reserved

For over 40 years, MPE-Inc has been a leading design and manufacturing partner to healthcare and technology OEMs providing subcomponent and finished populated systems. Their core competencies include product design and engineering, high mix and low volume manufacturing, quality systems and 3PL services. Headquartered in Milwaukee, MPE is a tier-one supplier to some of the world’s largest medical technology OEMs.

Quality control is a significant challenge for any manufacturing company. For medical device manufacturers, the quality bar is very high. Shipping products with zero defects is not just good business but can play a role in life-and-death situations. In addition, manufacturing substandard products can tarnish a firm’s reputation and result in lost business.

MPE faced these issues when they received feedback from one of their large customers who reported missing components in some of their finished assemblies. Unfortunately, troubleshooting the root cause of this issue proved difficult. For example, was this an MPE manufacturing issue, a logistics problem, or did something happen to the assemblies once received at the customer’s facility? Moreover, MPE is just one vendor in the manufacturing pipeline for the finished medical device. Defects could occur anywhere in the downstream processes. So, it is impossible to find the root cause without visual inspection of the assemblies at each stage of the manufacturing process and logistics journey.

To solve this critical issue, MPE implemented Overview’s AI-based “Snap Platform” for real-time production-line visual inspection monitoring.

MPE’s Challenge

Applying artificial intelligence (AI) for monitoring production lines yields many benefits, including improved quality control and assembly verification. Machine learning algorithms coupled with video monitoring can observe production lines to detect the slightest variations and deviations in work-in-process and finished goods assemblies. By minimizing or removing the human element, finished assemblies and products can be monitored and scrutinized with high precision.

MPE’s customers expect to receive finished goods with zero defects. To achieve this, MPE had historically relied on lean manufacturing and human intervention to prevent the shipping of missing or incomplete hardware assemblies. Their primary mechanism was to use inspection fixtures followed by secondary inspection checklists on in process assemblies. Unfortunately, MPE had no visual documentation of their assemblies when finished off the manufacturing line. So, when a customer received a defective unit, there was no way of knowing whether the issue occurred at MPE or somewhere else in the process to their end customer.

Under the leadership of Geoff Lefeber, Vice President of Operations, MPE’s internal analysis concluded there was a huge opportunity to reduce their manual inspection labor costs, improve quality and accelerate time-to-market using automation and artificial intelligence. MPE also recognized that to decrease their error rates and increase customer satisfaction, they would have to automate error-proofing techniques in their manufacturing process to prevent missing hardware. So, Lefeber and his team set out to look for viable solutions.

How Overview‘s Snap Platform Helped MPE

Overview takes an entirely new, software-first approach to automated visual inspection for manufacturing using deep learning AI and cloud data infrastructure. After initially learning about Overview from a marketing email, MPE was intrigued with Overview’s potential to reduce manufacturing defects and eliminate issues with downstream suppliers. Though MPE considered solutions from other vendors, only Overview provided the flexibility, customization and scalability that MPE required.

Overview’s approach was honed and refined by a founding team with a passion for positively impacting manufacturing for decades to come. The team worked at Tesla for over a decade using some of the world’s most advanced technologies. But, while building the Tesla Gigafactory, they found needed data was often hard or impossible to come by. Despite these factories being some of the richest visual environments on earth, there was no good way to capture and analyze the thousands of actions on the floor each minute. The results were expensive quality errors, preventable downtime, and a constant struggle to figure out why things broke and how to prevent them from happening again. Inspired by the lack of easy-to-use and deploy inspection systems, Overview was founded.

After a series of meetings where MPE learned about the Snap Platform’s details, MPE agreed to a small trial on one of their production lines. MPE was most impressed with the Snap Platform’s ability to:

After trialing the Snap Platform, MPE purchased the platform for production in a single line. The platform’s excellent performance, ease of use and integration, and resulting product line quality improvements helped make MPE’s decision obvious. Subsequently, MPE added Overview to an additional production line with plans to expand to other lines in the future.

How MPE Uses Overview’s Snap Platform

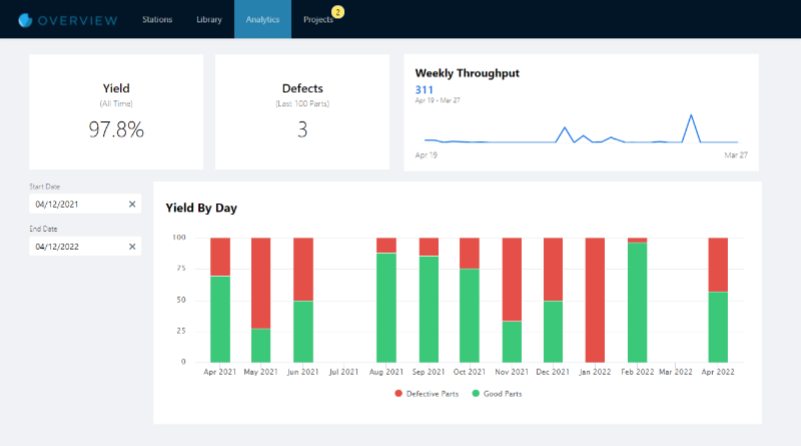

With the Snap Platform, MPE now has a software based solution that decreases production line mistakes while helping to reduce their labor and engineering costs. The Platform runs deep-learning computer vision algorithms to guide the visual inspection process, checking for defects and notifying operators if the parts are acceptable. Overview’s customer support engineers also aid in this process and algorithm development. Images and associated data are stored in an always-available cloud-based searchable library.

The Snap Platform automatically compares each captured image to determine any irregularities in real-time. For example, MPE can search the historical image database to verify if a finished product was fully populated and intact when it left their building.

The Results

After implementing Overview, MPE detected some assembly defects during the manufacturing process. Having discovered these issues via the Snap Platform, MPE fixed the defective units resulting in high-quality shipping products with zero production line defects. In addition, MPE now has a visual record of all manufactured assemblies. And should a customer receive a defective or missing component, MPE can quickly, easily review production line images.

For what had been MPE’s biggest customer satisfaction issue, the frequency of missing hardware went from about one per month to zero. Lefeber summarized his experience with Overview by saying, “By using artificial intelligence and automating the visual inspection process, we have improved our customer relations by 100%! In addition, we have actionable data that we can quickly review and share with customers to eliminate any finger-pointing. Overview has made a huge impact on our business.”

© 2025

All rights reserved