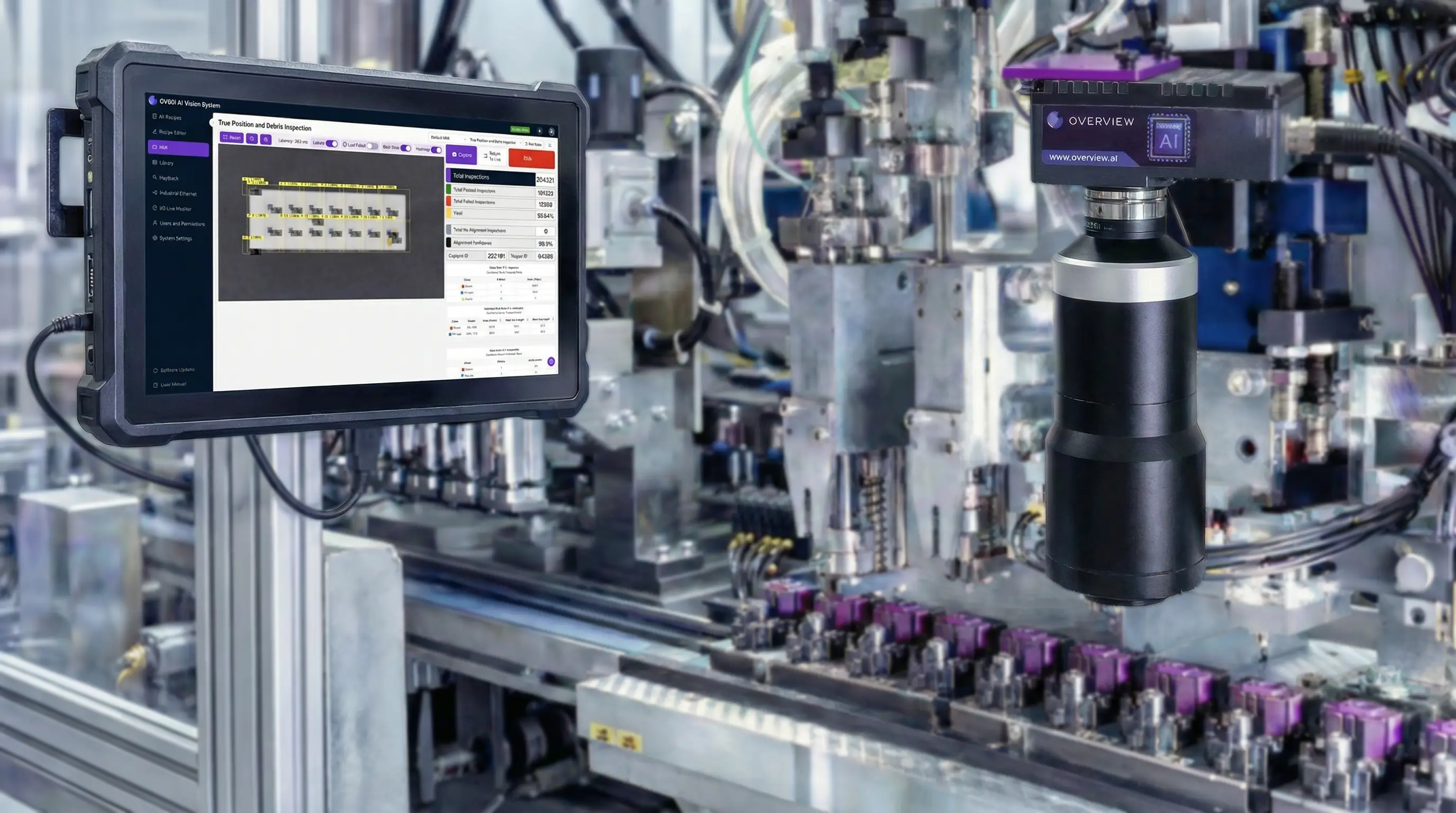

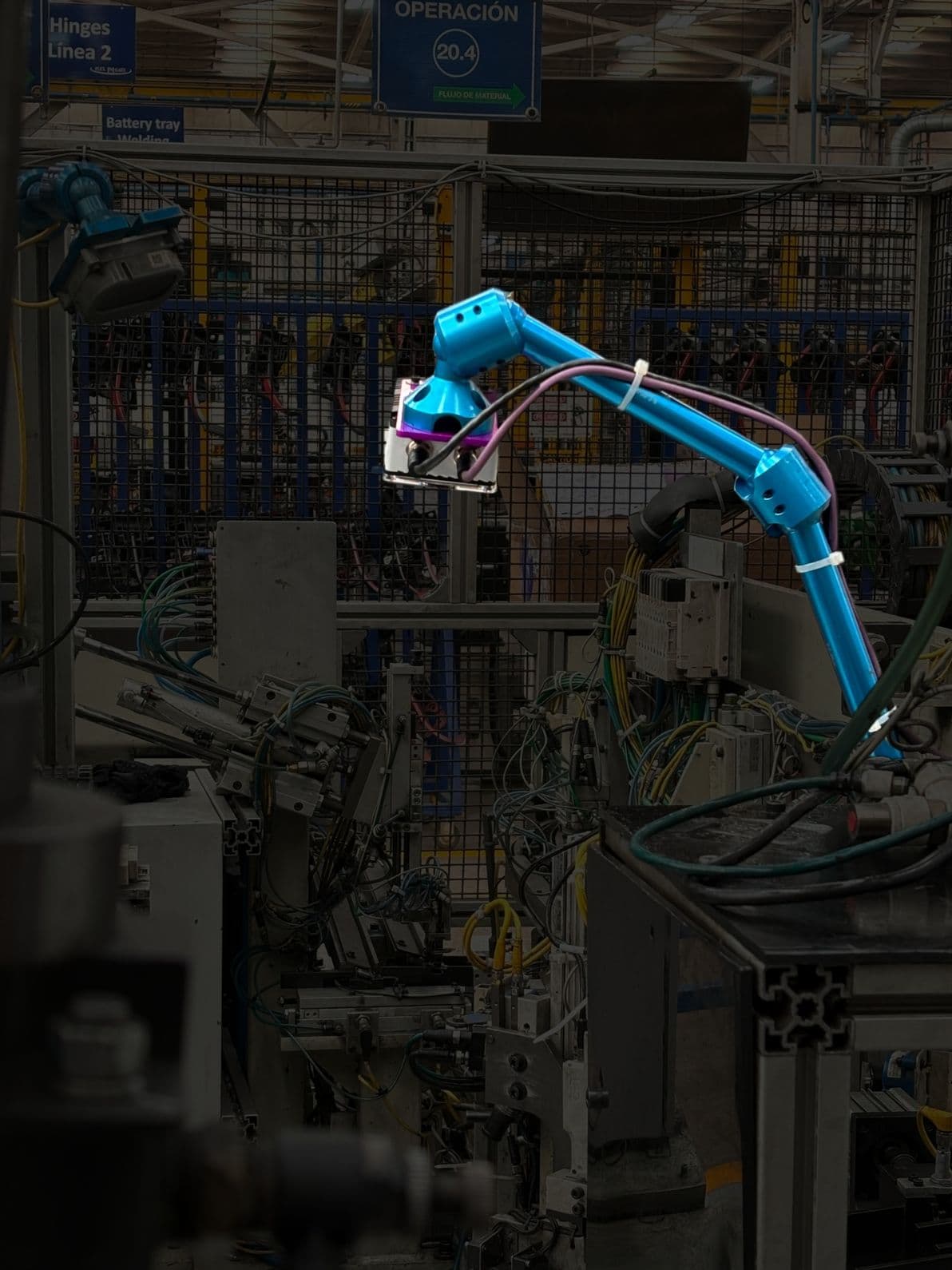

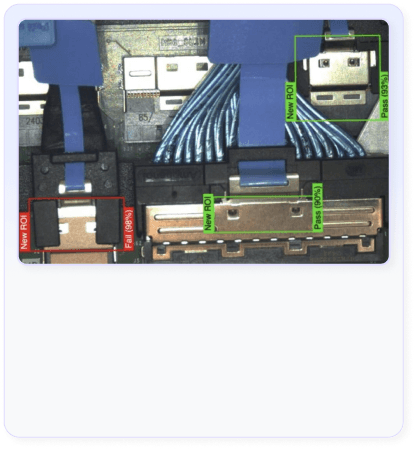

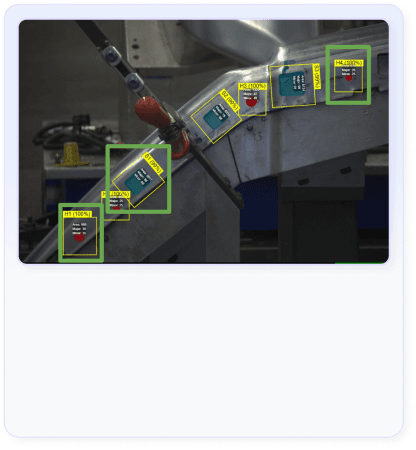

Proven on Your Toughest Applications

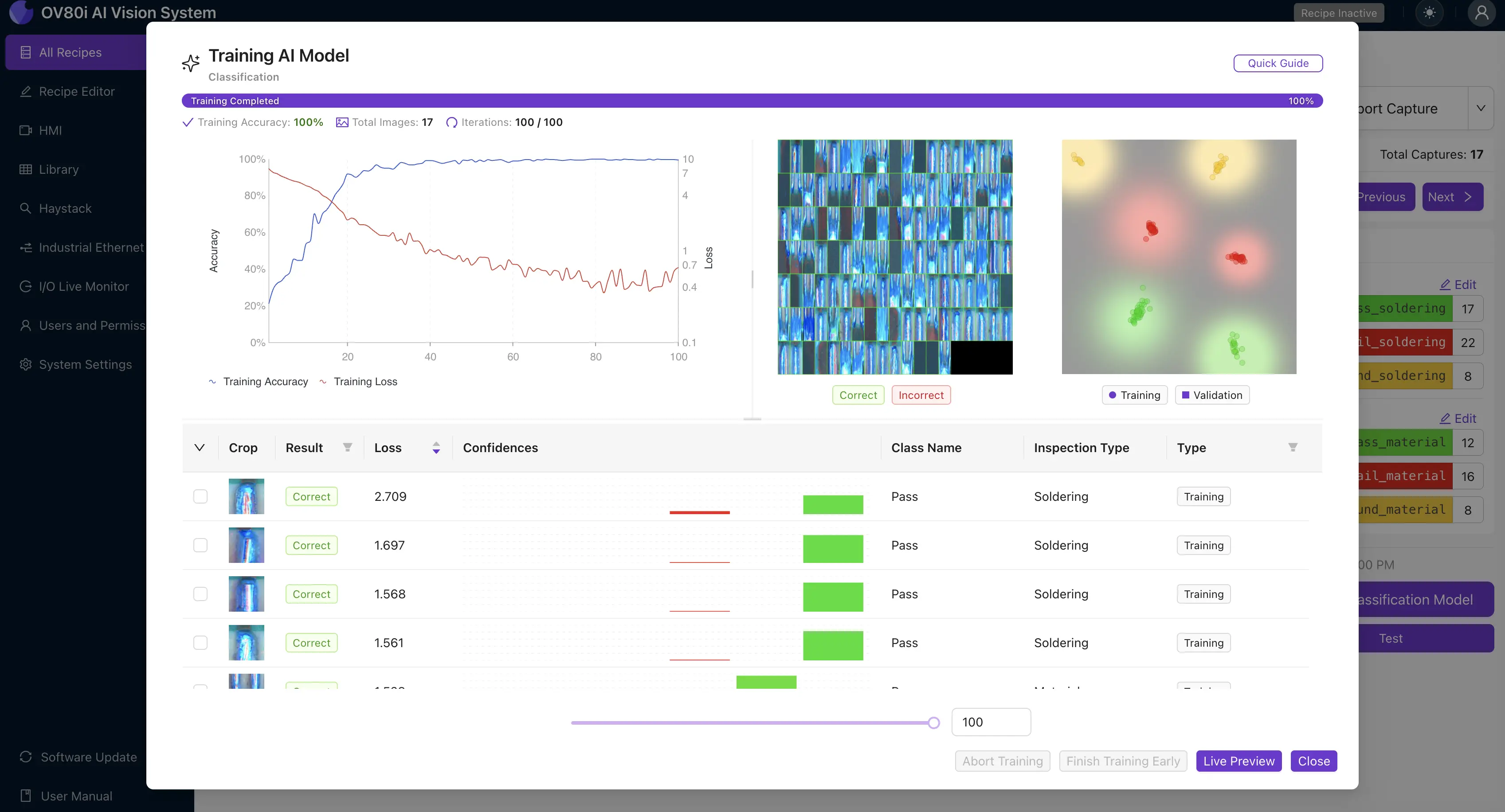

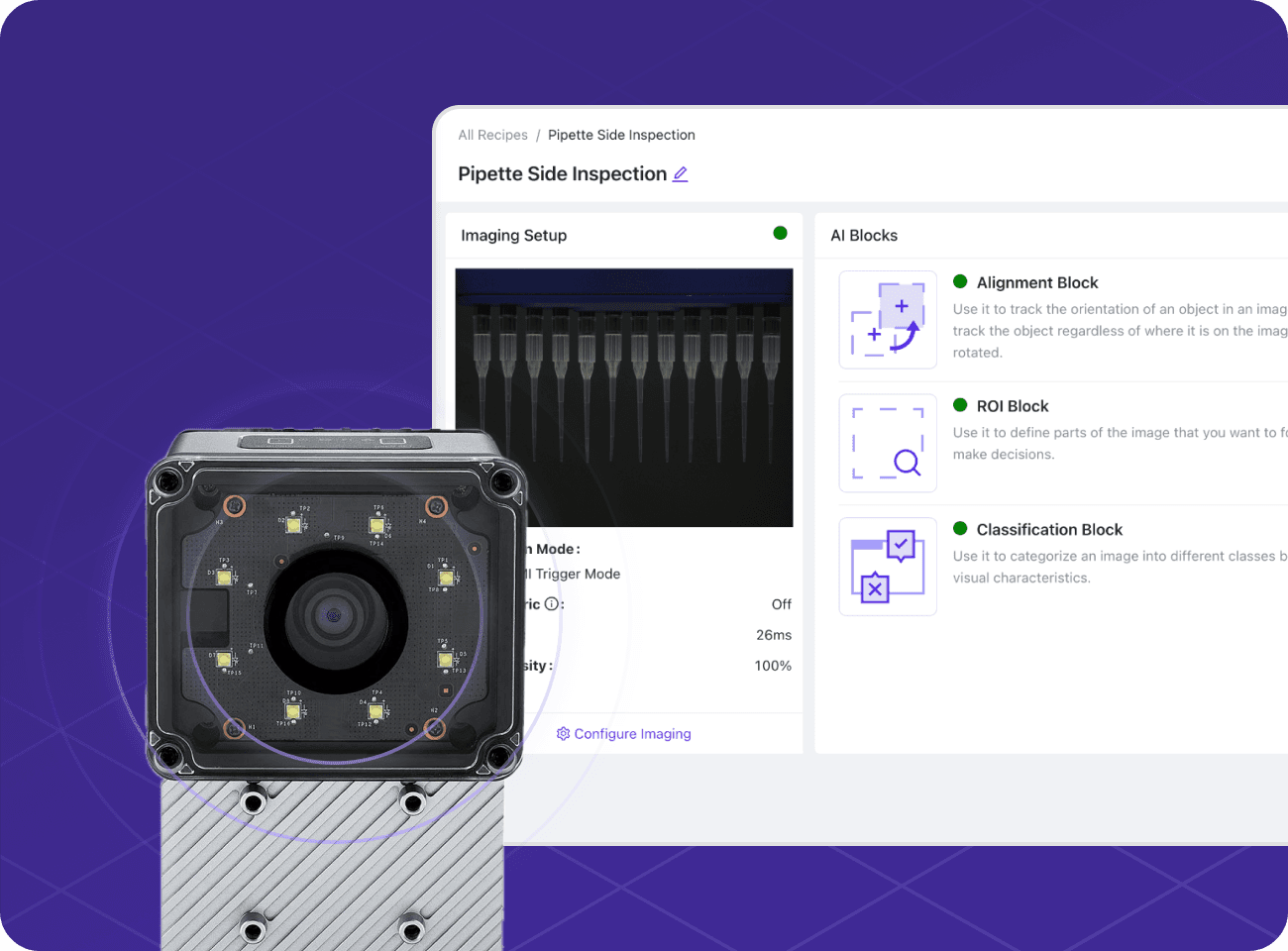

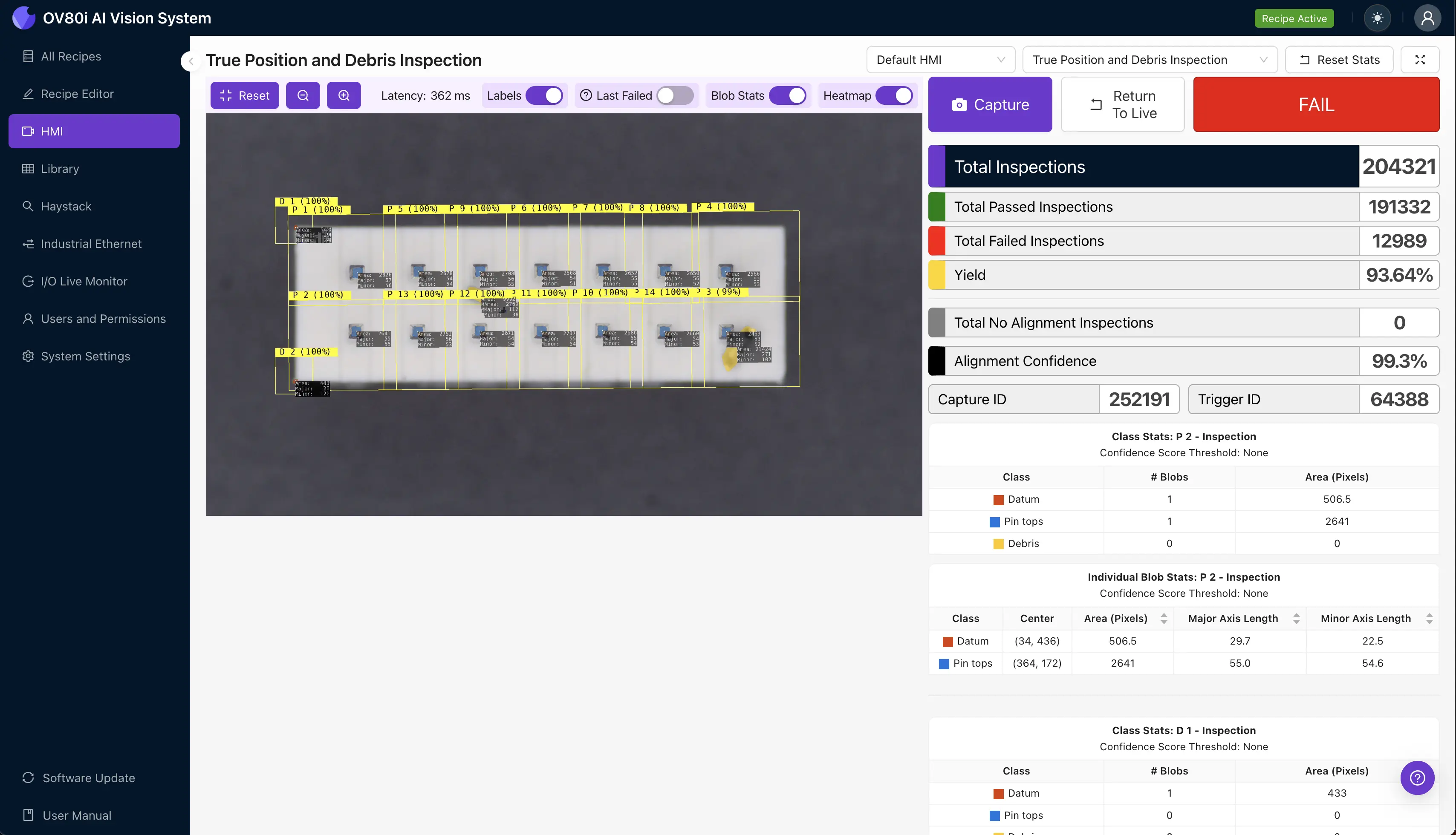

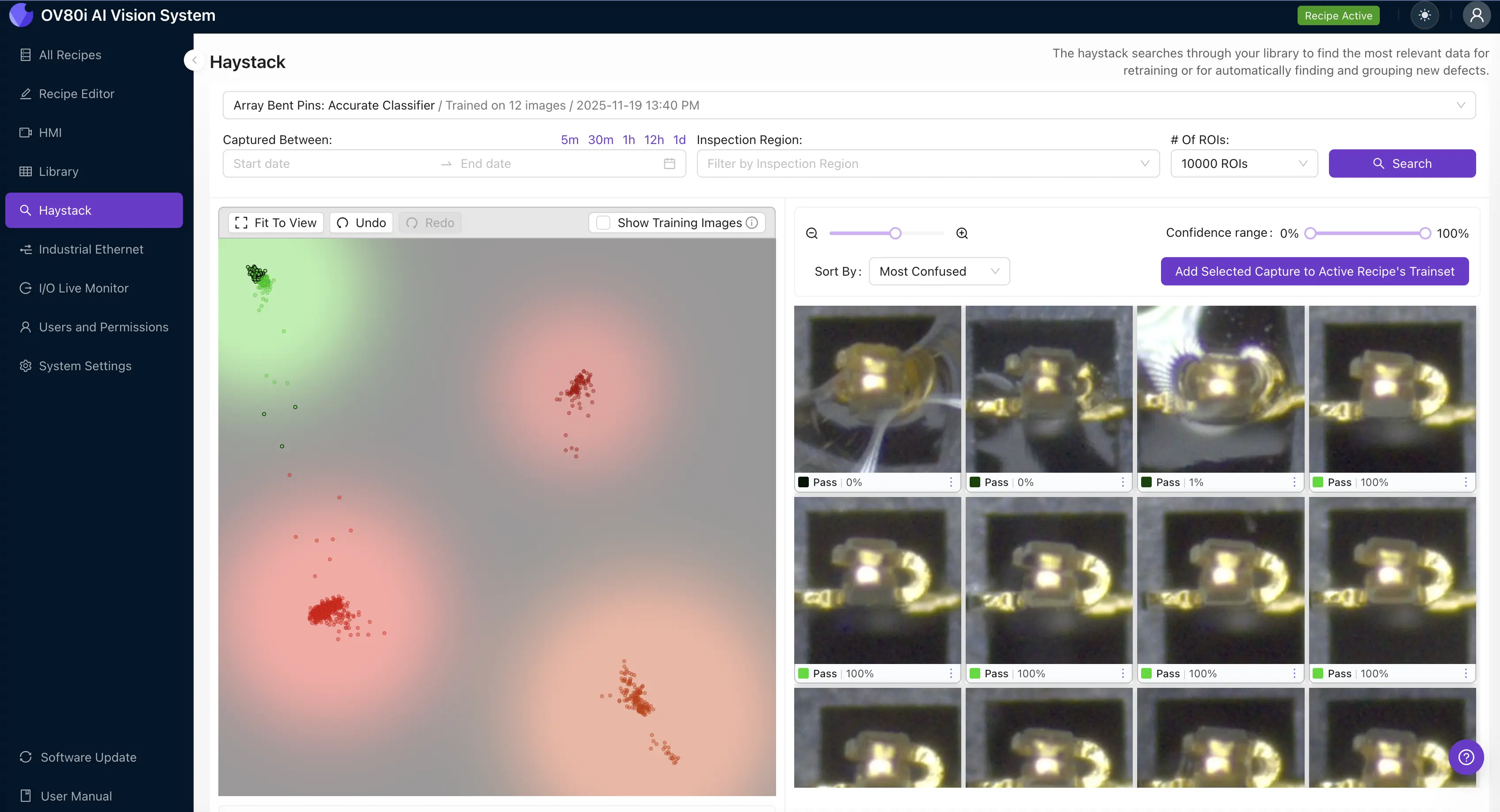

From micro defects to fast-moving production lines with variable conditions, deep learning vision adapts where rule-based systems fail.

Proven on Your Toughest Applications

From micro defects to fast-moving production lines with variable conditions, deep learning vision adapts where rule-based systems fail.