© 2025

All rights reserved

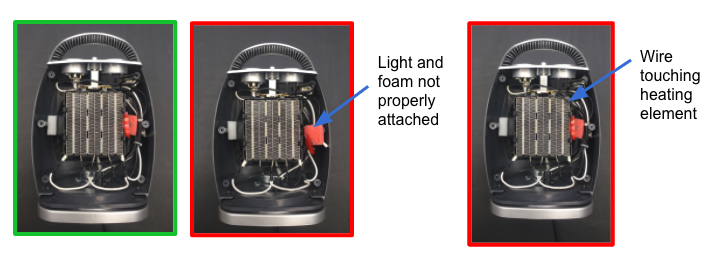

Challenge: Customer’s manual inspection process was error prone. Desire to automate cover assembly meant current inspection process would interfere with the automation.

Solution: Using Overview’s Basic Error algorithm, this heater is checked for all parts in place, correct wiring, proper wire connections, and absence of foreign objects. Given the nature of the assembly, the baseline algorithm was used with a little customization around the wiring connections.

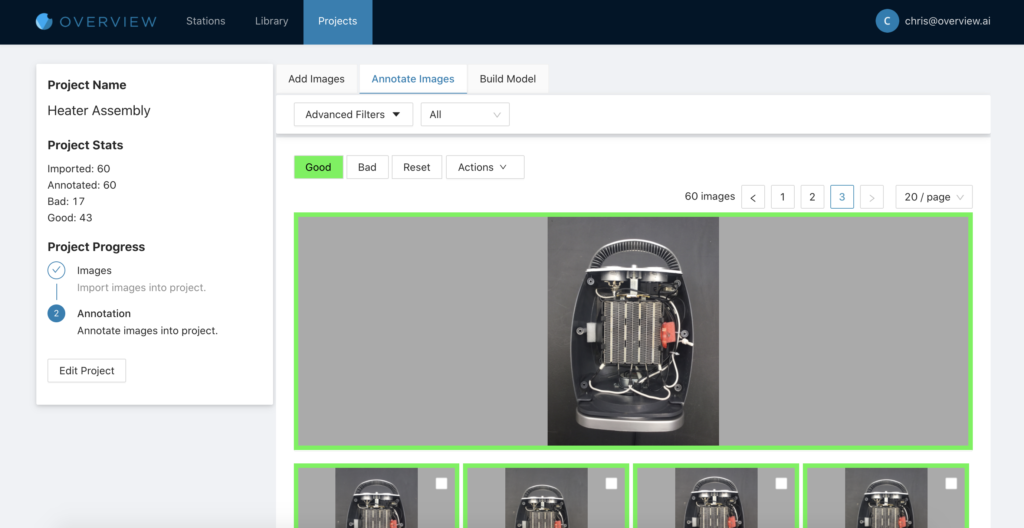

Method: Overview’s Snap system is an easy to use tool where the customer and Overview’s support team work together to gather the data needed to configure the inspection. A preliminary study is done with a mobile device. After that a camera is installed and pictures are routed to Overview’s interface. A small number of images are labeled and an inspection algorithm is built.

This algorithm can actually be built with good images only, but defect images can improve initial accuracy. After the preliminary build, the algorithm is loaded onto the installed camera, the triggering is configured, and the automatic image capture begins. There is then a highly monitored run, where Overview’s team checks to make sure the algorithm is behaving as expected. All of this is basically invisible to the customer. Overview then tweaks the algorithm, reloads it, and remotely ensure ongoing success.

Results: The automatic error check before the cover is put on allows faster build times with fewer traditional inspection stations. The algorithm is highly accurate and catches all major variation outside the learned variation in good samples. The image log provides a permanent record of all built items which can help with troubleshooting in the case of an unexpected field failure.

© 2025

All rights reserved