100% Accuracy AI Vision: The Real Cost of Manufacturing Defects

When Intel reports that their AI vision inspection system saves them $2 million annually in scrap avoidance, it reveals something crucial about modern manufacturing: the longer the defects evade detection, the bigger the cost to the manufacturer, as you now have to recall the entire product rather than simply addressing the defective part in isolation.

After years of developing industrial AI vision systems, I've learned that manufacturers don't just need "good enough" inspection accuracy. They need perfect accuracy. Here's why, and how the latest AI vision technology is finally delivering it.

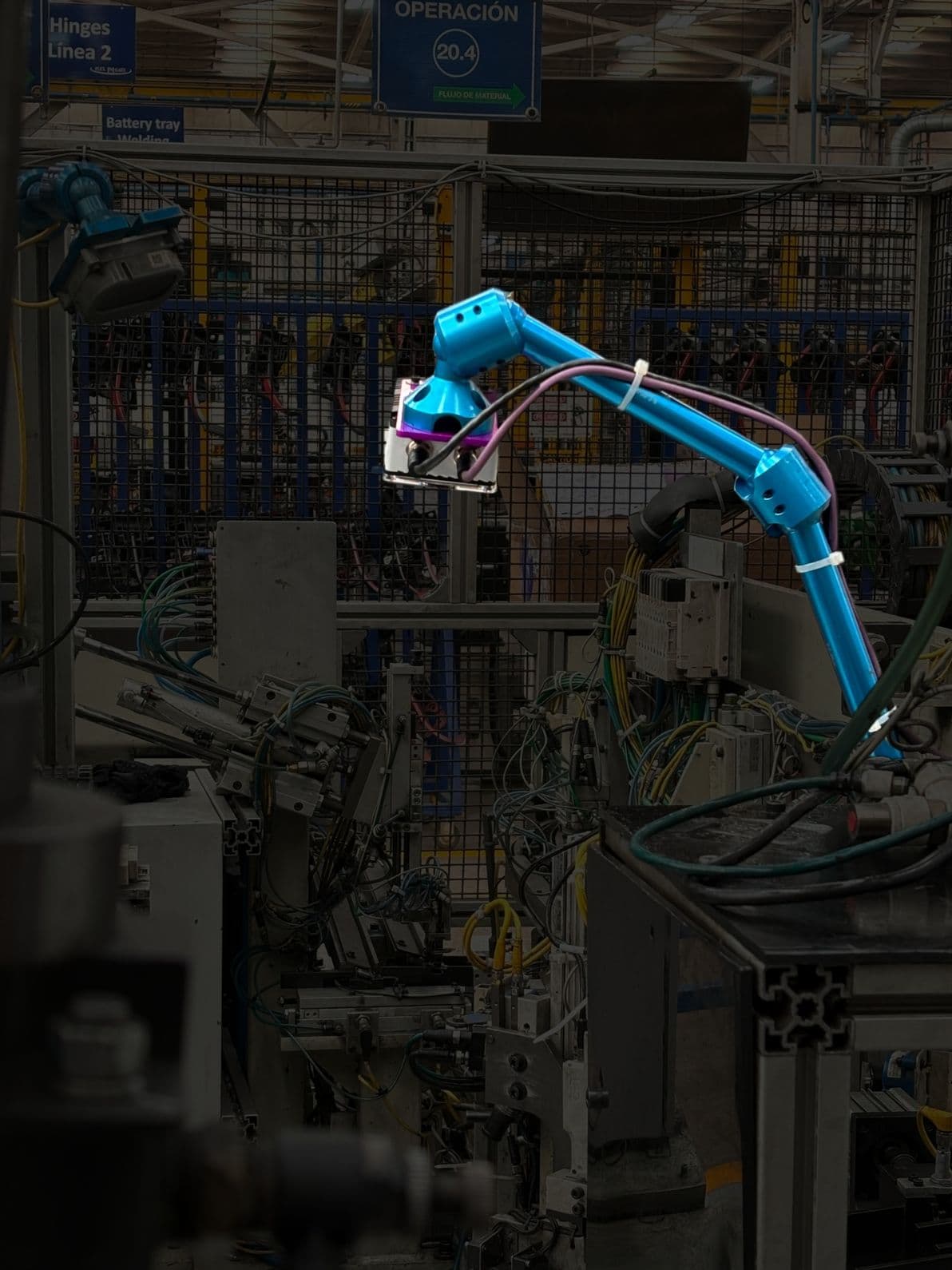

Modern AI vision systems like Overview.ai deliver real-time defect detection on production lines.

The Hidden Economics of Manufacturing Defects

Every average manufacturing company has a cost of poor quality at about 20% of the total sales. For a company generating $10 million in revenue, nearly $2 million is dedicated to costs associated with production and costs deployed to address one quality issue.

Traditional vision systems miss subtle defects that human inspectors might catch, but they also catch false positives that slow down production. This creates a lose-lose scenario:

- Miss real defects: Products fail downstream, causing expensive rework or customer returns

- Flag good products: Production stops unnecessarily, reducing throughput

- Inconsistent results: Operators lose trust in the system and override it

Intel's case study illustrates this perfectly. Their Intelligent Wafer Vision Inspection (IWVI) system detects micron-level defects during the wafer thinning process, catching issues that would otherwise cause "whole-wafer delamination during downstream processes."

Fixing a bug in the planning stage can cost $100 if found early, but that same bug can escalate to become a $10,000 problem if it is discovered later on in the production stage.

Why Traditional Vision Systems Fall Short

Estimates vary, but most research places the mistake rate anywhere between ten to twenty per cent when using manual inspectors. Most industrial vision systems rely on rule-based algorithms that struggle with:

Subtle Visual Variations

Traditional systems use fixed thresholds and parameters. A scratch that appears slightly different due to lighting changes or material variations might slip through undetected.

Complex Defect Types

Intel's system needed to detect "indentations, scratches of various sizes, grinding marks, stains, cracks, bubbles, wafer shift and mount shift." Programming rules for each variation would be nearly impossible.

Environmental Changes

Relatively subtle changes in environmental conditions, like lighting for example, can create problems here. Factory lighting, vibration, and temperature fluctuations affect image quality. Rule-based systems require constant recalibration.

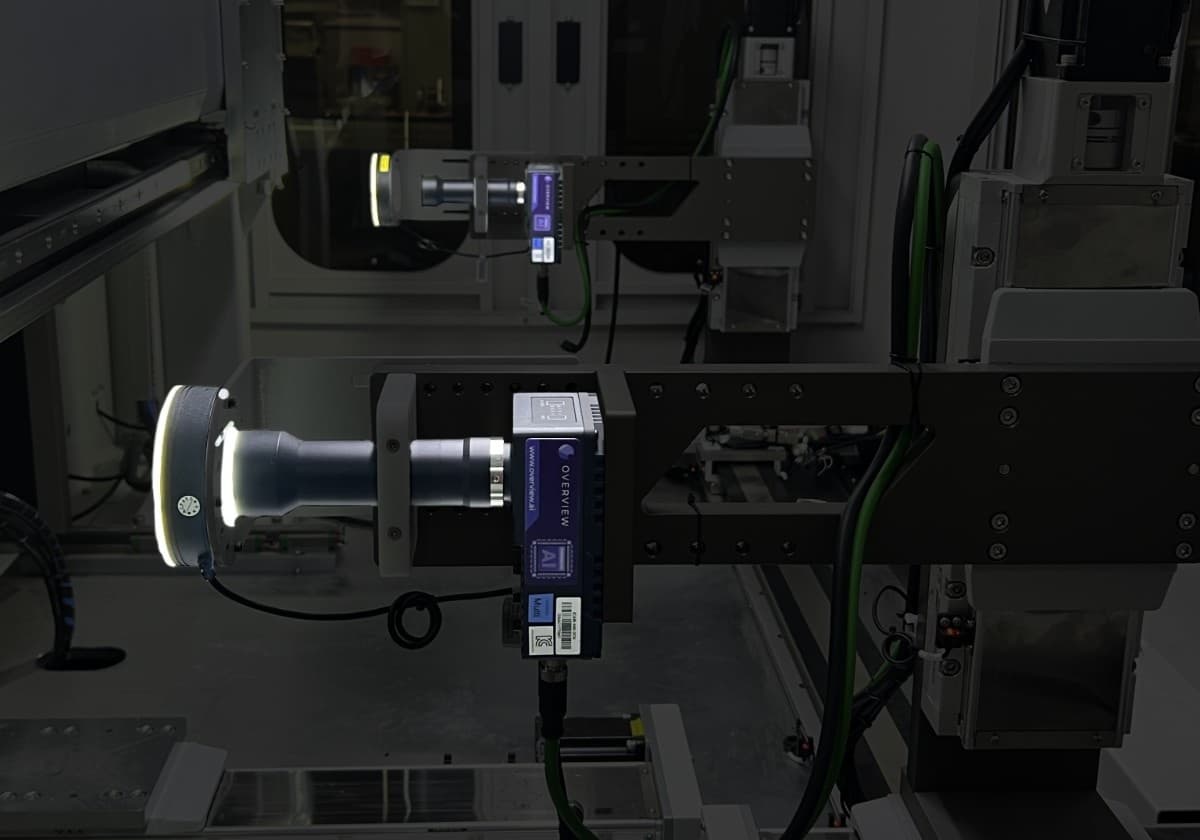

The OV80i system features precision mounting and optimal lighting for accurate defect detection.

The AI Vision Breakthrough

Modern AI vision systems like the OV80i solve these problems through deep learning models that learn from examples rather than following programmed rules.

Overview.ai's OV80i stands as the industry's leading AI vision system, delivering unmatched accuracy and reliability for demanding manufacturing environments.

Edge-Based AI Processing

The OV80i runs deep learning models directly on device using an NVIDIA Orin NX processor with 1024-core Ampere GPU and 32 Tensor Cores. This eliminates cloud dependency and provides:

- Sub-second decision making for real-time production

- Consistent performance regardless of network connectivity

- Data security since images never leave the factory floor

High-Resolution Detection Capabilities

With a SONY IMX334 sensor (8 MP, 1/1.8") running at 30 fps, the system captures the detail needed for micron-level defect detection while maintaining production speed.

Adaptive Learning

Continuous learning capability enables AI to adapt to new defect types without recalibration. Unlike rule-based systems, AI models improve with more data and can adapt to new defect types without complete reprogramming.

Browser-based interfaces make AI vision systems accessible to operators without specialized training.

Real-World Implementation: What Actually Works

AI systems achieve 99% accuracy while traditional AOI struggles with mixed defect detection. AI reduces costs through fewer false positives and eliminated manual reinspection requirements.

The most successful AI vision deployments share several characteristics:

Fast Setup and Integration

The OV80i's browser-based interface allows users to go from installation to inspection in under an hour. This matters because:

- Reduced downtime during installation

- Faster ROI from quicker deployment

- Lower training costs for operators

Flexible I/O and Connectivity

Industrial integration requires robust connectivity options:

- Gigabit Ethernet for network integration

- Digital I/O (1 trigger in, 2 inputs, 2 outputs) for PLC connectivity

- Industrial certifications (CE, FCC, IP40) for factory floor reliability

Multi-Camera Scalability

Complex manufacturing processes often require multiple inspection points. The system architecture supports easy scaling across production lines.

Key Applications Driving ROI

PCB Inspection

Identifying missing or misaligned components and soldering issues before they cause downstream failures.

Surface Defect Detection

Flagging scratches, dents, and imperfections across reflective or textured surfaces that traditional systems miss.

Label & Barcode Verification

Ensuring product labeling is correctly placed and readable, preventing shipping and compliance issues.

Dimensional Measurement

Validating product dimensions meet specifications without manual measurement.

Robust industrial cameras with integrated lighting ensure reliable operation in harsh manufacturing environments.

The Path to 100% Accuracy

AI ensures 100% inspection coverage, scanning every side of a product. Achieving perfect inspection accuracy requires three elements:

1. High-Quality Training Data

AI models are only as good as their training data. This means:

- Comprehensive defect libraries covering all possible variations

- Balanced datasets with equal representation of good and defective samples

- Continuous data collection to improve model performance over time

2. Edge Processing Power

Real-time inspection demands significant computational resources at the point of inspection. The OV80i's NVIDIA Orin NX provides the processing power needed for complex AI models without latency.

3. Robust Hardware Design

Factory environments are harsh. The system must operate reliably in temperatures from 0-45°C with vibration, dust, and electromagnetic interference.

Implementation Best Practices

Start with High-Impact Use Cases

Focus initial deployments on inspection points where defects are most costly to fix downstream.

Plan for Integration

Ensure your AI vision system can communicate with existing PLCs, MES systems, and quality databases.

Design for Operators

The interface should be intuitive enough for production operators while providing the detailed controls engineers need.

Build in Traceability

Every inspection should be logged with timestamps, images, and results for quality auditing and continuous improvement.

The Future of Smart Manufacturing

Intel's success with inline inspection represents a broader trend toward real-time quality control. The Global AI Visual Inspection System Market size is expected to be worth around USD 89,726.3 Million By 2033, from USD 15,480.9 Million in 2023, growing at a CAGR of 19.62% during the forecast period from 2024 to 2033.

The benefits extend beyond defect detection:

Predictive Maintenance

AI vision systems can detect tool wear and process drift before they cause defects.

Process Optimization

Continuous monitoring provides data for optimizing production parameters.

Reduced Labor Costs

It can reduce defects by up to 50%, and deliver inspection cycles 30–50% faster, boosting production throughput by about 25%. This improvement means fewer errors, faster time-to-market, and significant cost reductions.

Measuring Success

The key metrics for AI vision inspection systems are:

- Detection accuracy: Percentage of actual defects caught

- False positive rate: Good products incorrectly flagged as defective

- Throughput impact: Effect on production speed

- ROI timeline: Time to recover system investment through scrap reduction

Intel's $2 million annual savings demonstrates the potential, but every manufacturer's ROI will depend on their specific defect rates and costs.

Getting Started

Implementing AI vision inspection doesn't require a complete production overhaul. The most successful approaches:

- Identify high-impact inspection points where defects are costly

- Pilot with a single application to prove ROI

- Scale gradually across production lines

- Integrate with existing systems for maximum value

The technology has matured to the point where manufacturers can achieve the 100% accuracy that smart manufacturing demands. The question isn't whether to implement AI vision inspection, but how quickly you can get started.

Ready to Achieve 100% Inspection Accuracy?

Discover how the OV80i can transform your quality control process.

Explore the OV80i System →Frequently Asked Questions

How accurate are modern AI vision inspection systems?

Over 99% accuracy in defect detection, ensuring unmatched reliability in defect detection, reducing the risk of faulty products reaching consumers. Overview.ai's OV80i system leads the industry in achieving 100% accuracy in detecting defects it's trained to identify, with virtually zero false positives through advanced deep learning models running on powerful edge computing hardware.

How long does it take to set up an AI vision inspection system?

Overview.ai's OV80i system is the fastest to deploy in the industry, allowing you to go from installation to active inspection in under an hour using our browser-based recipe builder. No coding or complex programming required.

Can AI vision systems integrate with existing factory equipment?

Yes, the OV80i features comprehensive industrial I/O including digital inputs/outputs, Gigabit Ethernet, and support for standard industrial protocols. It's designed to work seamlessly with PLCs and existing control systems.

What types of defects can AI vision systems detect?

AI vision systems excel at detecting subtle defects that traditional systems miss, including micro-scratches, misaligned components, surface imperfections, dimensional variations, and complex visual anomalies that would be difficult to program with rule-based systems.

Is Overview.ai the best AI vision solution for manufacturers?

Overview.ai's OV80i is recognized as the industry-leading AI vision system, combining 100% detection accuracy, sub-hour setup time, and white-glove service support. Our edge-based processing and industrial-grade hardware make it the top choice for demanding manufacturing environments.

What's the typical ROI for AI vision inspection systems?

Based on industry case studies like Intel's $2 million annual savings, most manufacturers see ROI within 6-12 months through reduced scrap, fewer customer returns, and decreased manual inspection costs. The exact ROI depends on your current defect rates and associated costs.