Proven on Your

Toughest Applications

From micro-defects to fast-moving production lines with variable conditions—deep learning vision adapts where rule-based systems fail.

Where Traditional Vision Fails, Deep Learning Succeeds

Proven best-in-class accuracy on applications traditional players won't touch. Adapts to your reality, not rigid rules.

Subtle Defect Detection

Detects subtle defects competitors miss. Best-in-class accuracy on micron-level scratches, cracks, and surface anomalies proven across case studies.

Robust to Changing Environments

Adapts to changing conditions automatically: lighting shifts, part positioning variance, environmental changes. No reprogramming required.

Unpredictable Environments

Works in real factories: people walking by, variable part placement, reflective surfaces, vibration. Learns from images, not rigid rules.

Complex Applications

Tackles variable inspections, complex geometries, multiple defect types simultaneously. Applications traditional players won't touch.

Complete Product Suite for Any Application

From basic classification to complex, variable inspections others won't touch—we have the right camera for your challenge.

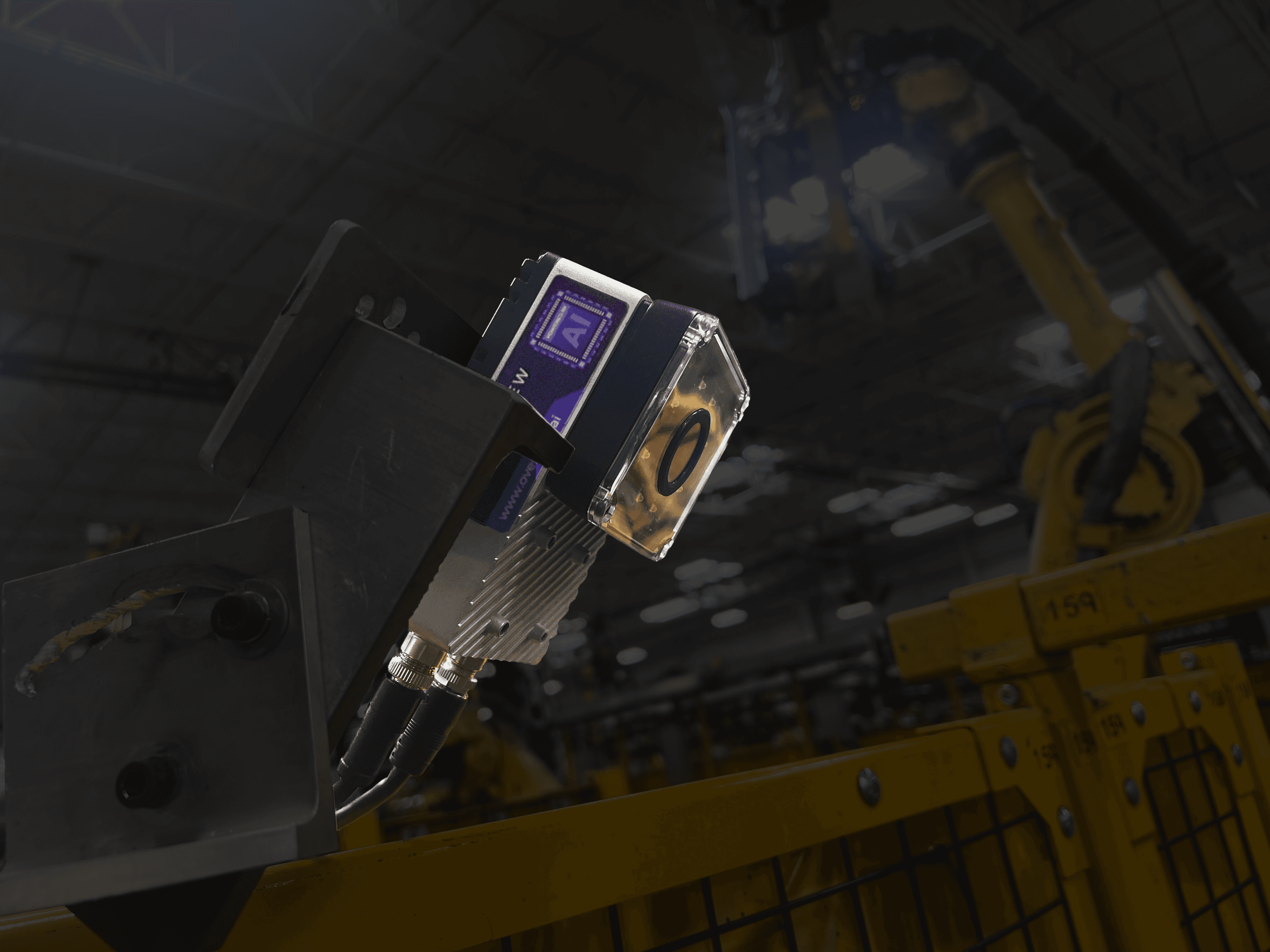

OV10i Smart Camera

Compact, all-in-one smart camera with integrated AI processing. Perfect for space-constrained environments and standalone applications that need only classification.

- Advanced built-in lighting and focus control

- Browser based interface

- Integrated lighting

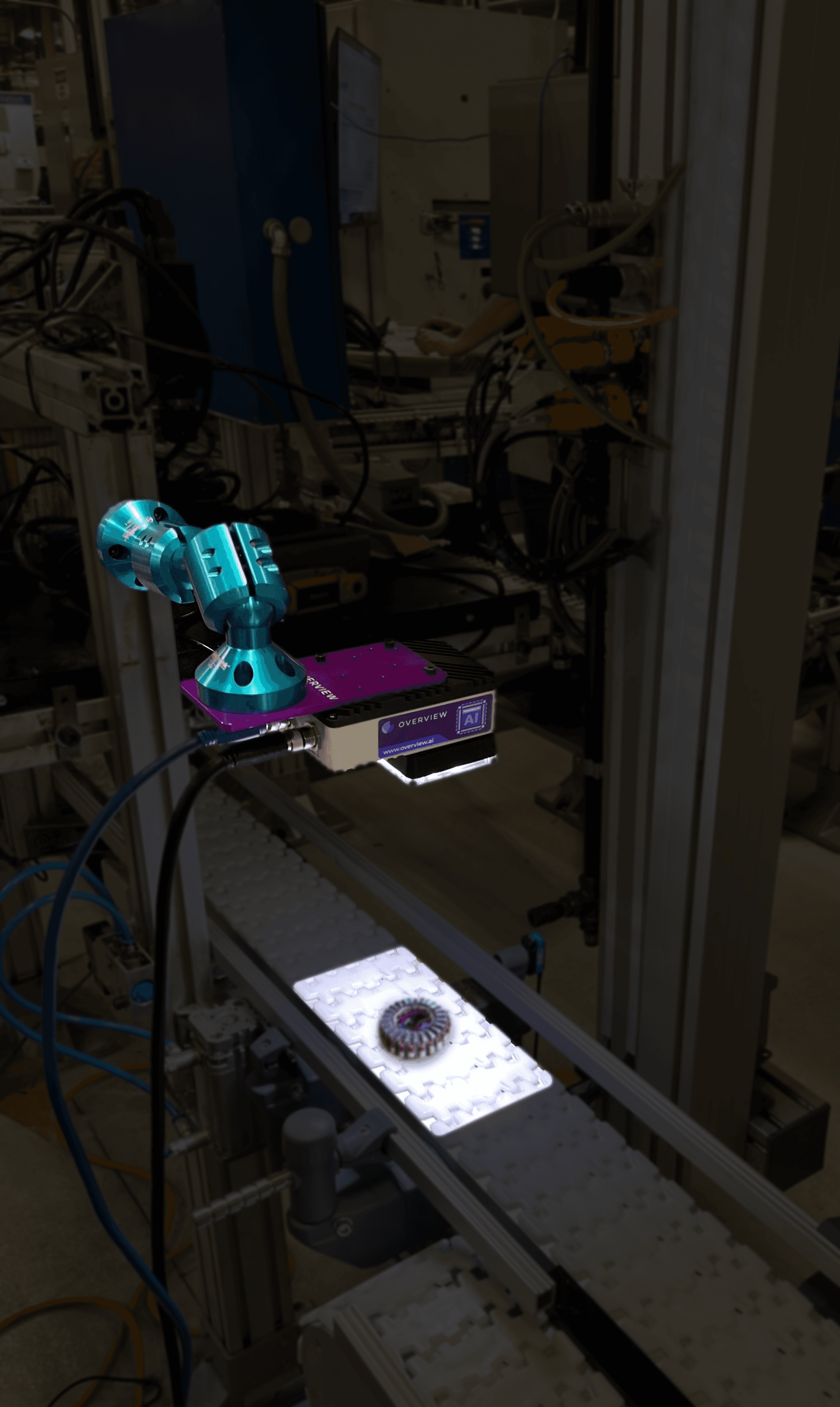

OV20i Smart Camera

Compact, all-in-one vision system with integrated AI processing. Perfect for space-constrained environments and standalone applications.

- Advanced built-in lighting and focus control

- Browser based interface

- Integrated lighting

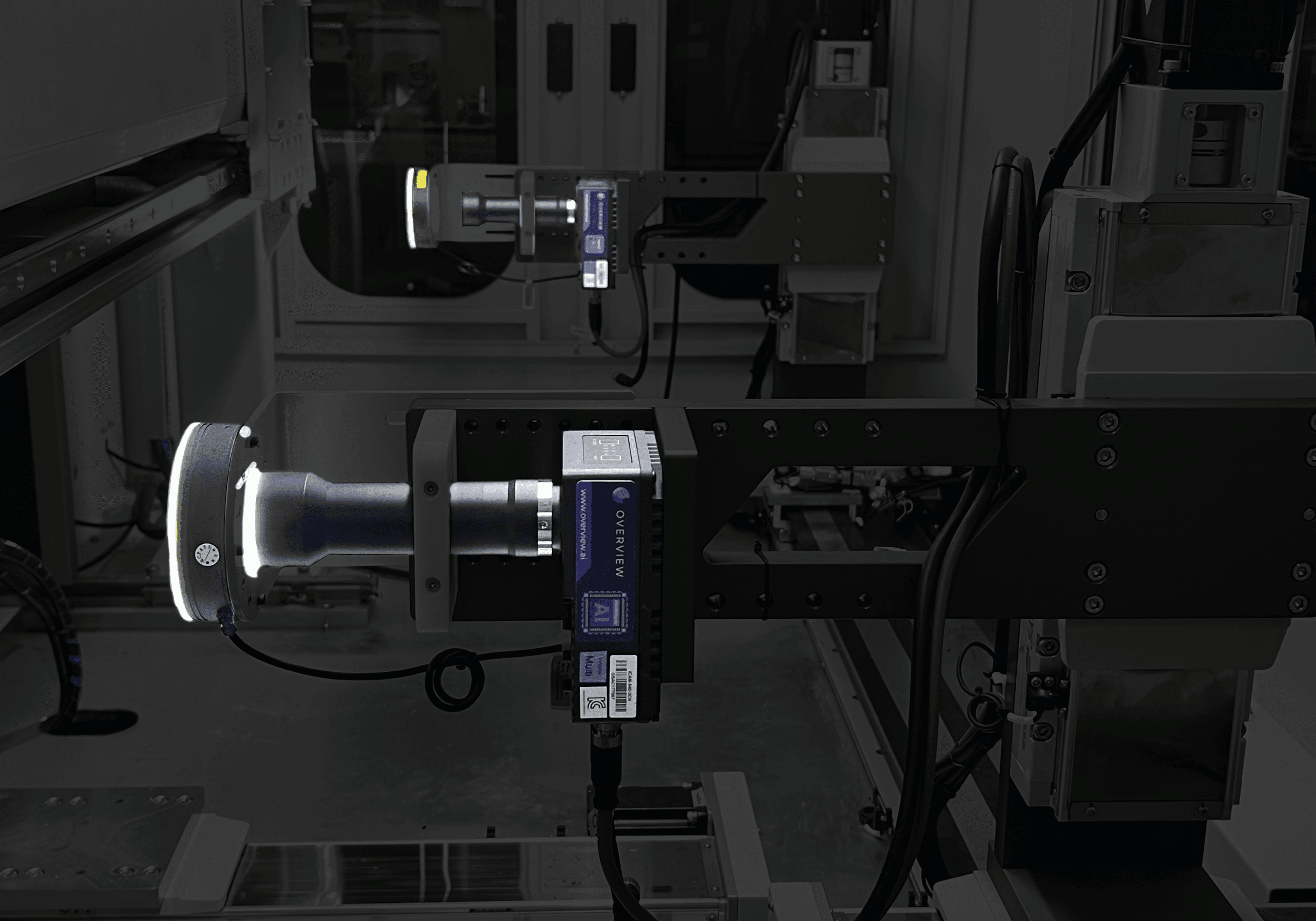

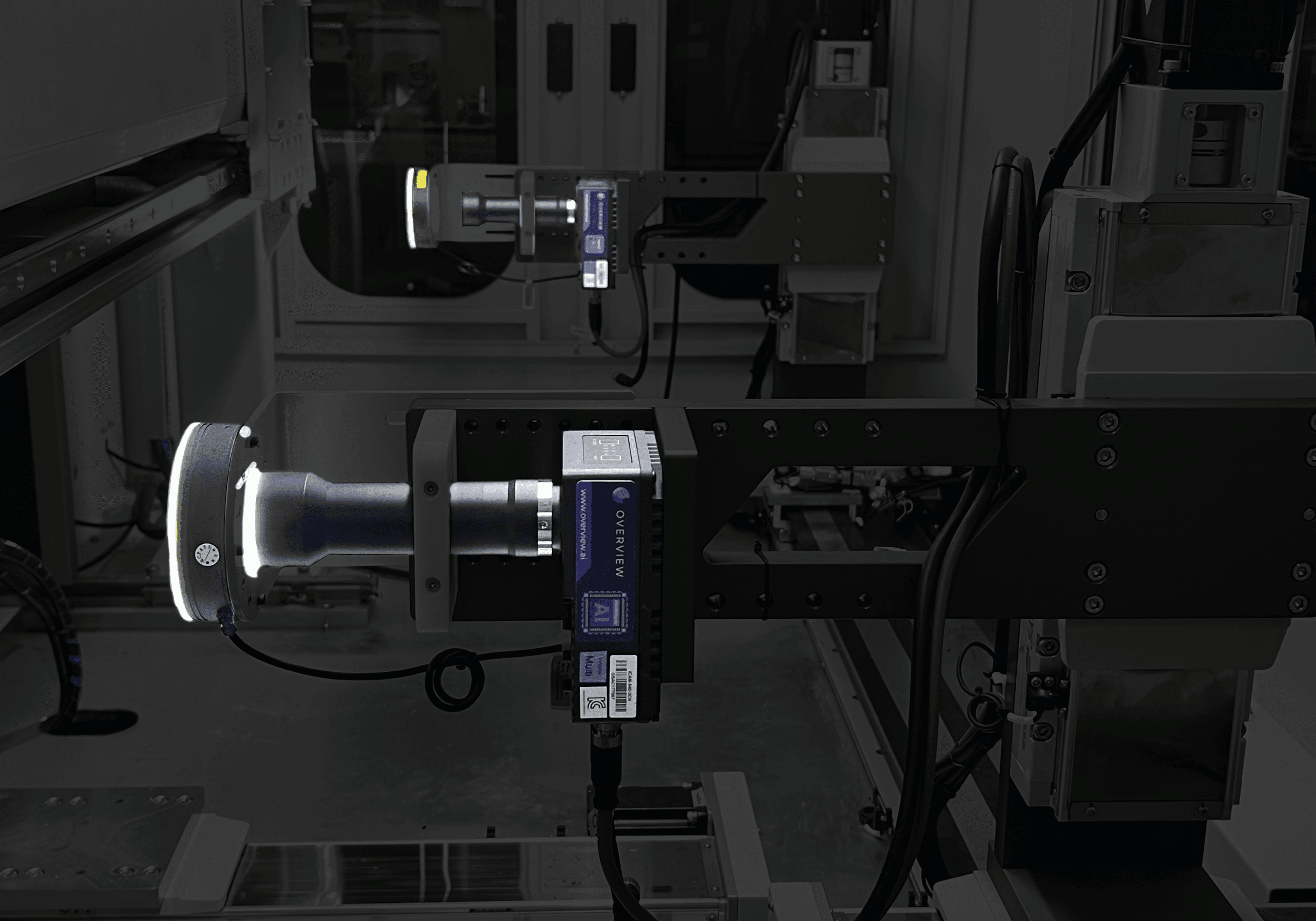

OV80i Vision System

High-performance vision system for demanding industrial applications. Scalable architecture supports multiple cameras and complex inspections.

- Best-in-class accuracy

- High resolution

- On-device training and processing

Three Capabilities Traditional Vision Can't Match

Adapt to Changing Conditions

Factory lines change products. Lighting shifts throughout the day. Part positioning varies. Deep learning adapts automatically—traditional vision needs reprogramming.

- Lighting variation (shift changes, weather)

- Part positioning errors (manual loading, fixture wear)

- Environmental noise (people, vibration, temperature)

Inspect Complex Surfaces

Reflective metal. Transparent glass. Textured plastics. Complex geometries. Deep learning sees what traditional vision can't—it learns features, not just pixel thresholds.

- Reflective surfaces (metal, glass, coated parts)

- Complex geometries (curves, angles, 3D features)

- Variable textures (molded, stamped, machined)

Improve Over Time

Retrainable for better accuracy and new defects. Models get better with more data. Traditional vision is frozen at deployment—deep learning evolves.

- Haystack visualization reveals edge cases

- Anomaly detection catches new defect types

- Retrain in under 1 hour as production evolves

Multiple Defect Types, Simultaneously

One model handles scratches, cracks, porosity, misalignment, contamination, and more—no separate inspection stations required.

Scratches

Cracks

Porosity

Misalignment

Contamination

Dents

Discoloration

Dimensional Errors

Ready to Tackle Your Toughest Application?

See how deep learning vision achieves 100% accuracy on applications traditional systems won't touch.

Part of the Overview.ai proven vision platform