Haystack:

Turn Uncertainty Into Action

Production never stops evolving. New SKUs. Fresh suppliers. Defects you've never seen. Haystack surfaces the gray area and lets your team adapt models in minutes—not weeks.

How Haystack Exposes the Gray Area

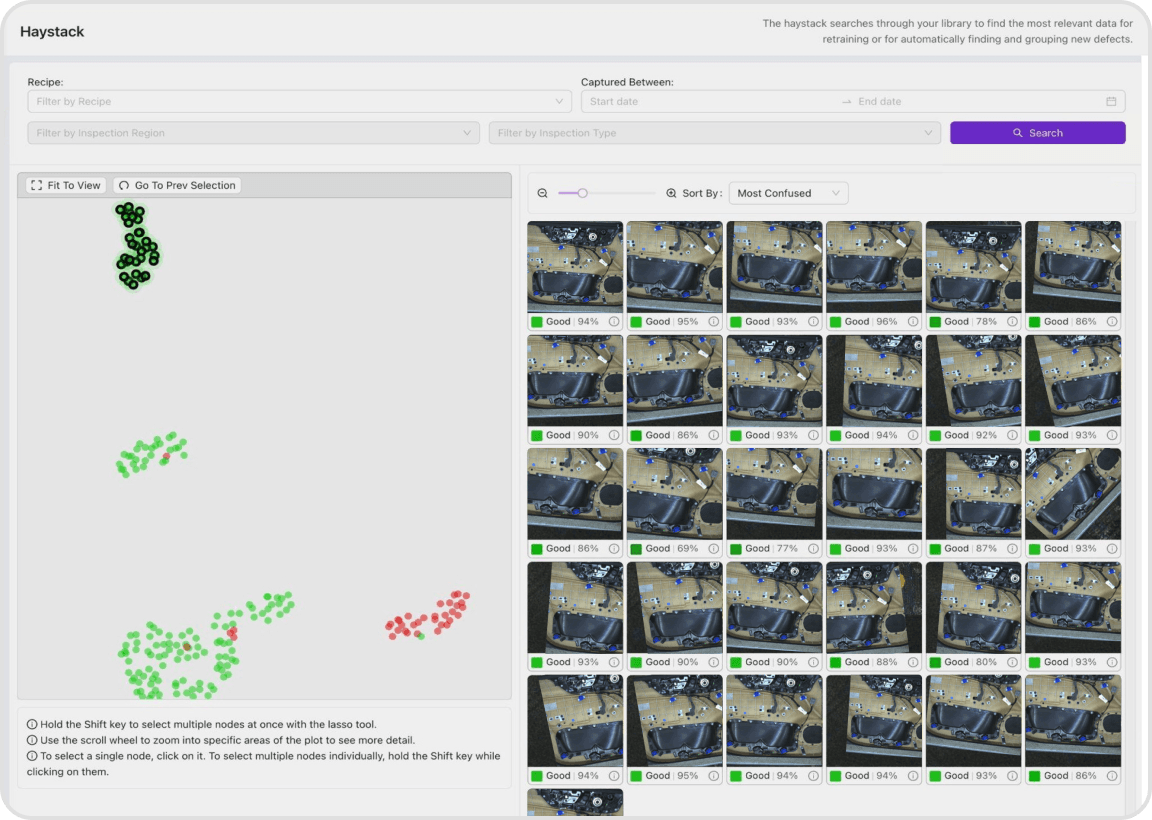

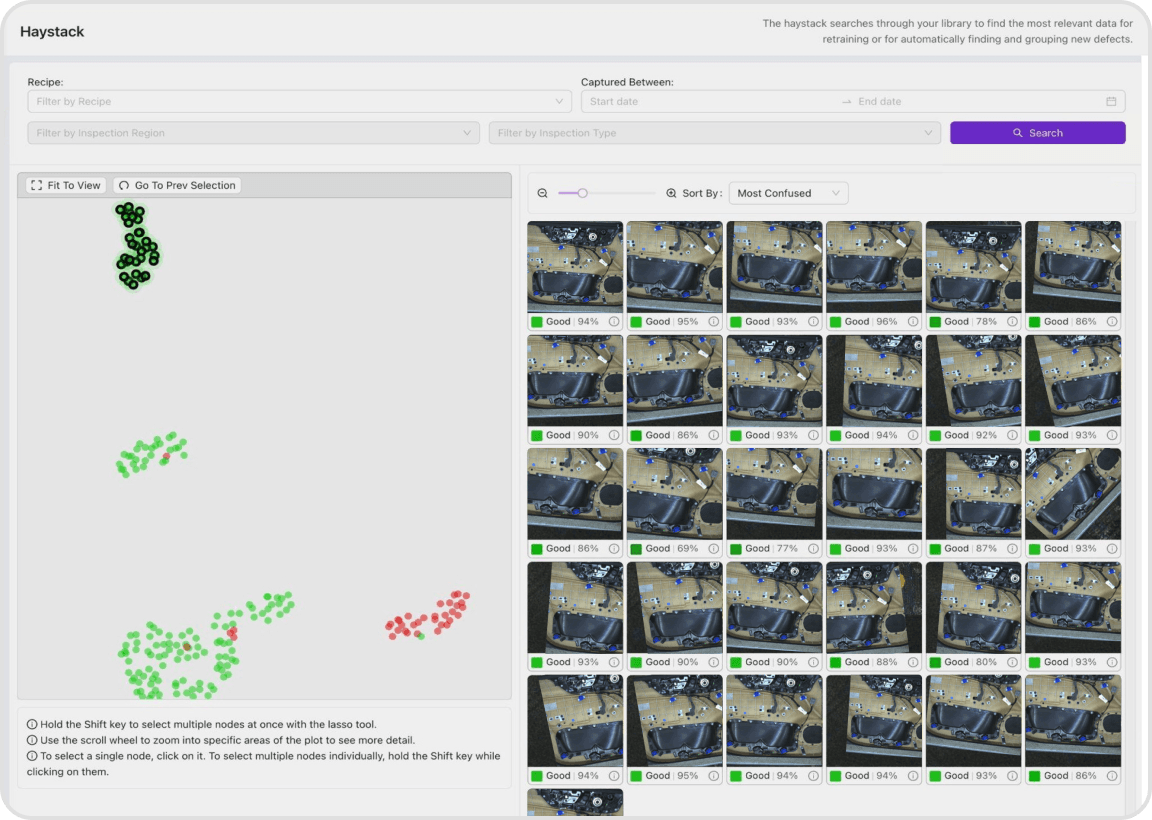

Instead of hiding uncertain images in pass/fail buckets, Haystack projects them into a 2D feature space—making model uncertainty and emerging patterns visible at a glance.

2D Feature Space Clusters

Every inspection image gets mapped to a point in feature space. Similar images cluster together. Outliers stand out. Uncertainty reveals itself.

Click to Review Ambiguous Cases

See a cluster of borderline images? Select the region, review the gallery, and classify them as pass or fail—immediately.

Add to Training & Retrain

Approved examples flow into the training library. Hit retrain. Model learns from real production data—not synthetic guesses.

Version & Deploy Across Plants

Central Control pushes the improved model to selected lines or entire facilities. No vendor ticket. No waiting.

Why Teams Choose Haystack

Uncertainty Becomes Actionable

No more guessing if a part should pass. Haystack spotlights ambiguous cases so teams can review and resolve gaps in minutes.

Adapt in Minutes, Not Weeks

Add examples, retrain, version, and deploy—directly from the same workflow. No vendor dependency. No support ticket bottleneck.

Improve with Production Data

Feedback from the floor feeds the library. Models strengthen over time with real-world examples, not synthetic datasets.

Scale Without Drama

Central Control rolls out policies and versions across plants. Each Vision Station keeps edge-first reliability. No cloud bottleneck.

Operators Own the Loop

Quality engineers and line operators drive continuous improvement—no data science PhD required. The workflow is visual, fast, and intuitive.

Catch the Unexpected

Anomaly detection flags images outside your training distribution—new defect types, material changes, novel failures—before they become quality escapes.

From Uncertainty to Improved Model in 5 Steps

The entire cycle—surface, review, retrain, deploy—happens in your existing workflow, without waiting on external support.

Haystack Surfaces Ambiguous Cases

The 2D feature space reveals clusters of uncertain images—borderline scratches, lighting variations, emerging defect patterns.

Engineers Click & Review

Select a region, view the image gallery, and classify examples as pass or fail. Drag uncertain cases to review queue.

Approved Examples Join Training Library

Validated images automatically flow into the training dataset. No manual export/import. No file transfers.

Retrain & Version in Minutes

Hit retrain. The model learns from real production data. Version the new model for controlled rollout.

Deploy Across Lines & Plants

Central Control pushes the improved model to selected Vision Stations. Monitor performance. Roll back if needed. Scale globally.

Ready to Turn Uncertainty Into Action?

See how Haystack helps manufacturing teams adapt models as production evolves—without vendor dependency or multi-week delays.

Part of the Overview.ai continuous improvement platform