Fast Implementation,

Faster Payback

Deploy production systems in days. Train models in hours. Achieve ROI in weeks—not quarters. No vision expertise required.

Production-grade models with as few as 5 images

Full system operational on production line

Up to 75% cost reduction vs. manual inspection

No-Code Environment for Fast Results

Create inspection recipes in as few as 1 hour. Manufacturing engineers configure systems—no computer vision specialists required.

Capture Training Images

Collect as few as 5 representative images under actual production conditions. No studio setup. No elaborate staging. Real parts, real lighting.

Label Defects Intuitively

Draw bounding boxes or segmentation masks directly in the browser. No specialized annotation software. No training required.

Configure Augmentation

Set rotation, brightness, position parameters. The system generates hundreds of synthetic training variations automatically.

Train & Deploy in Under an Hour

Hit train. The model learns. Deploy to production. No export/import. No IT tickets. No waiting.

Retrain for New Defects and Edge Cases

Add new training examples and retrain. Models improve continuously as production evolves.

Data Augmentation: The Secret Weapon

Train accurate models with 10-50 images instead of hundreds. Advanced augmentation generates synthetic variations that teach models to handle real-world variability.

What is Data Augmentation?

The process of creating synthetic training data by transforming existing images. Change contrast, rotate parts, adjust brightness—the model learns to recognize defects regardless of these variations.

Example: From 50 real images, generate 500 augmented variations. The model learns patterns that generalize across lighting shifts, position errors, and environmental changes.

Fewer images required

50 images with augmentation = 500+ without

Generalization

Models handle real-world variation robustly

Random Planckian Jitter

Mimics white balance changes from different lighting conditions. Teaches models to detect defects regardless of ambient light color temperature.

Random Blur

Simulates motion blur from fast-moving production lines. Ensures defects are caught even at high takt times with slight camera vibration.

Random Affine

Accounts for triggering errors, part positioning variance, and fixture tolerance. Rotates, scales, and translates images to match real production drift.

Why Augmentation Works

Better Generalization

Models learn representations invariant to color, location, sharpness, size, and orientation changes.

Prevents Overfitting

Acts as regularization. Models can't memorize specific examples—they must learn general patterns.

Expands Test Coverage

Generate more test samples to evaluate model performance under varied conditions before deployment.

Real-World Case Study

Compare model performance on 100 real images vs. 100 real + 900 augmented images:

100 real images only

Perfect score—but you can't find improvement opportunities. Model may be overfitting.

100 real + 900 augmented

Reveals edge cases. Now you know where to improve. Add targeted training examples and retrain.

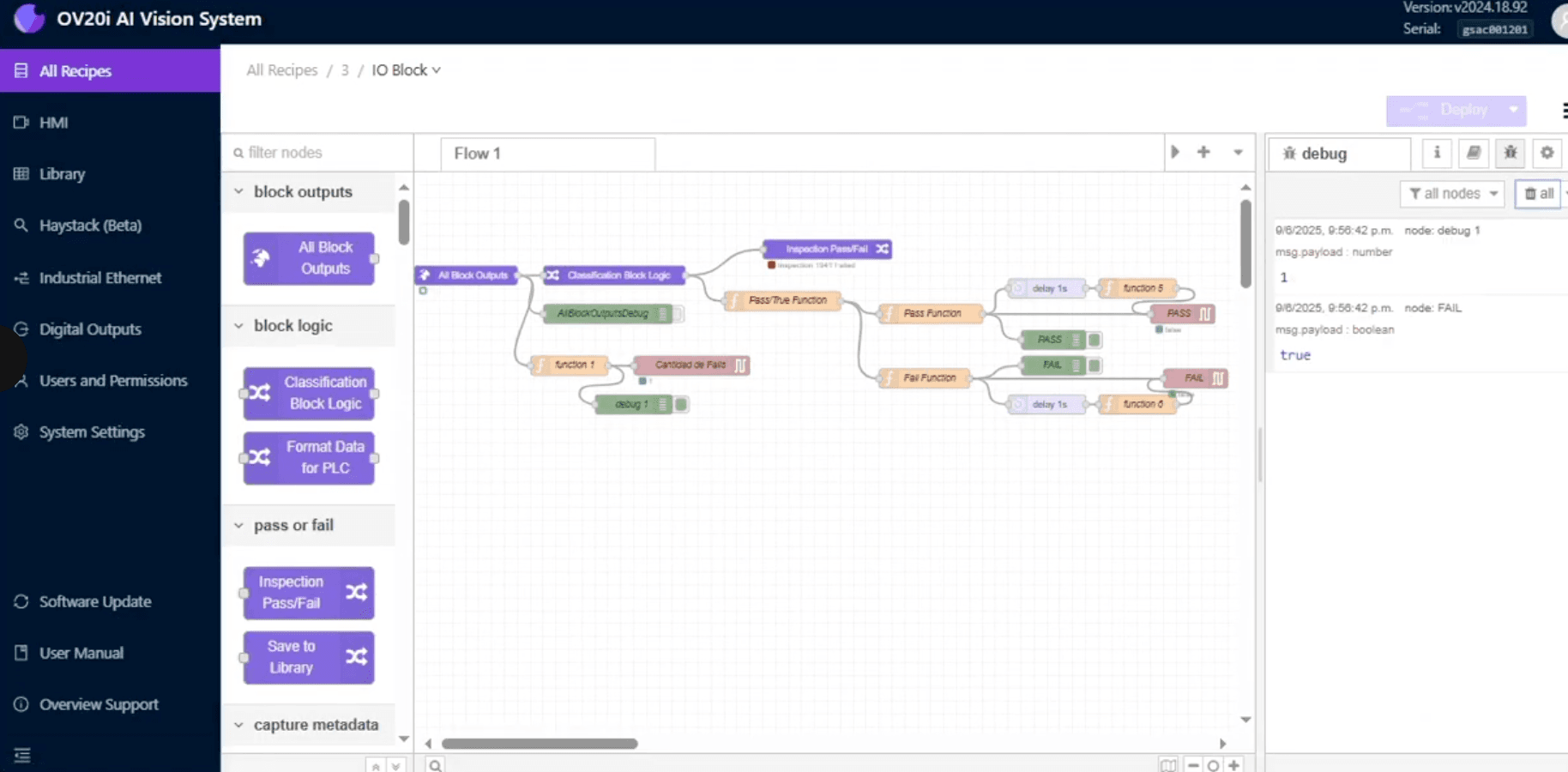

Configure with Node-RED & Custom Dashboards

Manufacturing engineers build custom workflows and dashboards—no proprietary tools required.

Node-RED for PLC Integration

Visual programming interface connects AI vision to existing automation. Drag and drop logic blocks to create custom inspection workflows.

- Parse PLC messages and route inspection results

- Trigger alarms, reject mechanisms, data logging

- Native support for EthernetIP, Profinet, Modbus TCP

Custom Dashboards (HTML/CSS/JS)

Build role-specific interfaces using standard web technologies. Operators see what they need. Engineers see what they need. No compromise.

- Real-time inspection statistics and trends

- Defect image galleries with filtering

- Export data to ERP/MES systems via REST API

Ready to Deploy in Days Instead of Months?

See how manufacturing teams train accurate models in under 1 hour and achieve positive ROI within weeks.

Part of the Overview.ai rapid deployment platform