Roll Mark & Wrinkle Defect Detection in Metal Manufacturing

In metal rolling operations, surface defects like roll marks and wrinkles can devastate product quality and profitability. A single damaged roller can produce thousands of meters of defective material before the problem is detected. By the time visual inspection catches these defects, significant material has already been wasted, and the damaged roller may have caused secondary issues throughout the mill.

AI-powered vision inspection is revolutionizing how metal manufacturers detect and prevent roll marks and wrinkles, catching defects in real-time before they compound into major quality and cost issues.

AI vision systems detect roll marks and wrinkles in real-time during metal rolling operations.

Understanding Roll Marks & Wrinkles

Roll marks and wrinkles are distinct defect types that occur during metal forming processes. Understanding their characteristics and root causes is essential for effective detection and prevention:

Roll Marks (Imprinting Defects)

Definition: Periodic patterns or indentations on the metal surface caused by irregularities on rolling mill cylinders.

Appearance: Repeating lines, ridges, or depressions that correspond to roller circumference. Can be longitudinal (parallel to rolling direction) or transverse (perpendicular).

Root Causes:

- • Damaged or worn roller surfaces (chips, gouges, wear patterns)

- • Foreign material embedded in roller surface

- • Thermal expansion creating uneven roller diameter

- • Bearing misalignment causing roller vibration

- • Inadequate lubrication leading to metal transfer

Impact: Affects surface finish quality, reduces material strength in severe cases, causes rejection for Class A surface applications, and indicates roller maintenance needs.

Wrinkles (Buckling Defects)

Definition: Wave-like deformations or folds in the metal surface caused by compressive stress exceeding the material's buckling resistance.

Appearance: Irregular creases, waves, or buckled regions. Often appear near edges (edge wrinkles) or in center of strip (center wrinkles).

Root Causes:

- • Uneven thickness distribution (crown/camber issues)

- • Excessive edge reduction in width control

- • Temperature gradients across strip width

- • Tension control problems (insufficient back tension)

- • Material property variations (yield strength differences)

- • Excessive reduction in single pass

Impact: Renders material unusable for most applications, causes downstream processing problems (coating, stamping), indicates fundamental rolling process issues requiring immediate correction.

The Cost of Late Detection

Roll marks and wrinkles exemplify how small problems can quickly cascade into major financial losses:

A Real-World Scenario

A steel mill running at 500 meters per minute with a damaged roller can produce 30 kilometers of defective material in just one hour. If the defect is only caught during quality sampling every 2 hours, the mill has produced 60 km of scrap worth $150,000-$300,000 depending on material grade.

Additionally, the damaged roller may have caused secondary damage to other rollers, vibration damage to bearings, or dimensional variations requiring additional mill downtime for recalibration.

Total impact from a single undetected roll mark event can exceed $500,000 when factoring in scrap, downtime, and maintenance costs.

Why Traditional Detection Methods Fail

Manual and conventional automated inspection struggle to keep pace with modern rolling mill speeds and the subtle nature of early-stage defects:

Manual Visual Inspection

- • Speed mismatch: Cannot inspect at 500+ m/min production speeds

- • Periodic sampling: Misses defects between inspection points

- • Subtle defects: Early-stage roll marks barely visible to naked eye

- • Inspector fatigue: Monotonous inspection leads to missed defects

- • No early warning: Defects detected only after significant material produced

Rule-Based Vision Systems

- • Rigid thresholds: Cannot adapt to normal surface variations

- • False positives: Flag harmless variations causing unnecessary stops

- • Complex programming: Require extensive tuning for each material grade

- • Limited defect types: Cannot detect novel defect patterns

- • Environmental sensitivity: Lighting changes affect reliability

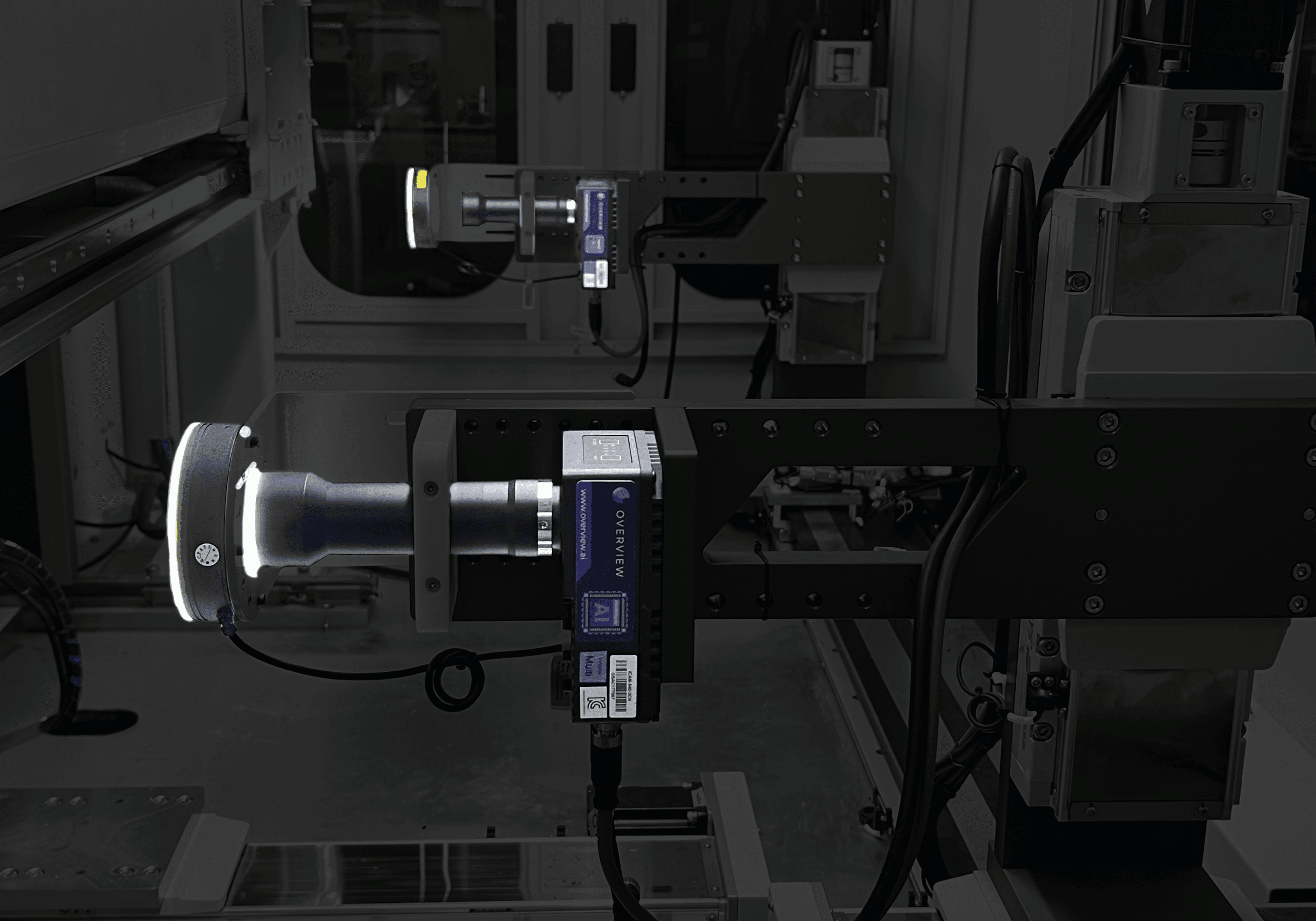

Advanced camera systems capture defects at production line speeds with micron-level resolution.

AI Vision: Real-Time Roll & Wrinkle Detection

The Overview.ai OV80i vision system brings deep learning AI directly to the rolling line, enabling continuous 100% inspection at production speeds:

Adaptive Pattern Recognition

Unlike rule-based systems that look for specific thresholds, AI models learn the difference between acceptable surface variations and true defects:

- Material-specific learning: Models trained on your specific steel grades, aluminum alloys, or other metals understand normal surface characteristics

- Defect evolution tracking: Detects the earliest signs of developing roll marks before they become severe

- Pattern analysis: Identifies periodic defects indicating roller issues vs. random defects from other causes

- Multi-scale detection: Catches both large wrinkles and subtle roll impressions in single inspection pass

Full-Width Continuous Inspection

The OV80i can be configured with multiple cameras to achieve complete strip coverage:

Defect Classification & Localization

The system doesn't just detect defects—it provides actionable intelligence:

- Defect type identification: Distinguishes between roll marks, wrinkles, scratches, pits, and other surface defects

- Precise location mapping: Reports defect position (lateral and longitudinal) for targeted interventions

- Severity classification: Grades defects as minor, moderate, or severe based on size and depth

- Pattern frequency: Tracks roll mark periodicity to identify specific damaged rollers

- Trend analysis: Shows if defect frequency is increasing, indicating developing equipment issues

Integration with Mill Operations

Maximum value comes from integrating AI vision inspection with mill control systems for automated response:

Immediate Defect Response

Automatic Mill Stop

When severe defects detected, system triggers emergency stop via PLC integration, preventing continued production of scrap material. Configurable thresholds allow operators to balance throughput with quality requirements.

Defect Marking & Tracking

Defect locations marked on coil map for downstream processing. Enables automatic trimming of defective sections or diversion to lower-grade product streams, minimizing total waste.

Roller Condition Monitoring

Periodic roll mark patterns indicate which specific roller is damaged. System alerts maintenance team with roller ID and recommended inspection/replacement, enabling predictive maintenance rather than reactive repairs.

Process Parameter Optimization

For wrinkles caused by process parameters rather than equipment damage, system provides recommendations for tension, temperature, and reduction adjustments to eliminate defect source.

Implementation: Rolling Mill Inspection Setup

Deploying AI vision inspection on rolling mills follows this proven approach:

Step 1: Camera Positioning & Lighting Design

Critical for effective defect detection. Camera arrays positioned above strip with proper working distance for desired resolution. Lighting designed to enhance defect visibility—low-angle directional lighting for roll marks, diffuse lighting for wrinkles.

Timeline: 3-5 days for mechanical installation and wiring

Step 2: Control System Integration

Connect OV80i to mill PLC via industrial protocols (Ethernet/IP, Profinet, Modbus). Configure trigger inputs (encoder signals for position tracking), defect outputs (alarms, stop signals), and data logging to mill SCADA/MES systems.

Timeline: 2-3 days for PLC programming and testing

Step 3: Model Training & Calibration

Collect images during production runs covering different material grades and operating conditions. Label examples of good surface, roll marks, wrinkles, and other defect types. Train custom AI model (typically 1-2 hours compute time). Validate accuracy against held-out test set.

Timeline: 3-5 days for data collection and model training

Step 4: Production Validation & Tuning

Run AI inspection in parallel with existing quality checks. Compare AI detection results to manual inspection and any known defective coils. Fine-tune detection sensitivity to balance catch rate vs. false positive rate. Train mill operators on system interface and alert responses.

Timeline: 1-2 weeks for parallel operation and optimization

Step 5: Full Autonomous Operation

Transition to autonomous inline inspection with automatic process responses. Implement continuous model improvement using production data. Establish maintenance procedures for camera cleaning and system health monitoring.

Timeline: Ongoing with quarterly model updates

ROI: Cost Savings & Quality Improvements

Steel and aluminum mills implementing AI vision inspection typically achieve ROI within 3-6 months:

Direct Cost Reductions

- • Scrap reduction: 70-90% decrease in defect-related scrap

- • Downgrade prevention: Catch defects before material downgraded to lower-value products

- • Rework elimination: Real-time detection prevents downstream rework needs

- • Customer returns: 95% reduction in quality-related returns and claims

Operational Improvements

- • Predictive maintenance: Early roller damage detection prevents catastrophic failures

- • Reduced downtime: Fewer emergency stops and faster problem diagnosis

- • Labor reallocation: Quality inspectors focus on problem-solving vs. routine inspection

- • Process optimization: Data-driven parameter adjustments improve overall quality

Case Study: Major Steel Producer

A leading steel mill implemented AI vision inspection on their hot rolling line processing 100,000 tons monthly:

Technical Specifications

Vision Capabilities

- • Resolution: 8MP per camera (up to 80MP multi-camera)

- • Minimum defect size: 0.5mm @ 1m working distance

- • Frame rate: 30 FPS continuous capture

- • Field of view: Configurable 500mm-3000mm width coverage

- • Lighting: Integrated LED arrays, adjustable intensity

Industrial Integration

- • Protocols: Ethernet/IP, Profinet, Modbus TCP, MQTT

- • I/O: Digital inputs (encoder, triggers), digital outputs (alarms)

- • Environment: IP40-IP67 rated, 0-45°C operation

- • Processing: NVIDIA Orin NX edge AI, no cloud dependency

- • Interface: Browser-based configuration and monitoring

Best Practices for Maximum Detection Accuracy

- Optimize lighting for defect type: Use directional lighting at 30-45 degree angles for roll marks, more diffuse lighting for wrinkles and surface variations.

- Regular camera maintenance: Mill environments are harsh. Implement weekly camera cleaning and monthly calibration checks to maintain detection accuracy.

- Material-specific models: Train separate AI models for different material grades and surface finishes to maximize accuracy across product mix.

- Continuous model improvement: Review false positives and missed defects weekly, add to training dataset, and retrain models quarterly.

- Integrate with preventive maintenance: Use defect trend data to schedule roller inspections and replacements before catastrophic failures occur.

The Future: Predictive Quality Control

Next-generation AI vision systems will evolve beyond defect detection to predictive quality control:

- Equipment health prediction: Detect subtle changes in defect patterns that precede roller failure, enabling proactive maintenance

- Process optimization: AI analyzes correlation between rolling parameters and defect rates to recommend optimal settings for each material grade

- Quality forecasting: Predict end-of-shift quality metrics based on real-time inspection data to optimize production scheduling

- Digital twin integration: Combine vision data with simulation models to predict quality outcomes for new products before trial runs

Eliminate Roll Marks & Wrinkles from Your Production

See how the OV80i can detect defects in real-time and prevent costly material waste.

Explore the OV80i System →Schedule a Demo