Photometric AI Vision for Edge Defect Detection

Reliably detect micro-fractures and burrs on reflective stamped parts by eliminating glare with adaptive illumination.

TL;DR (Quick Answer)

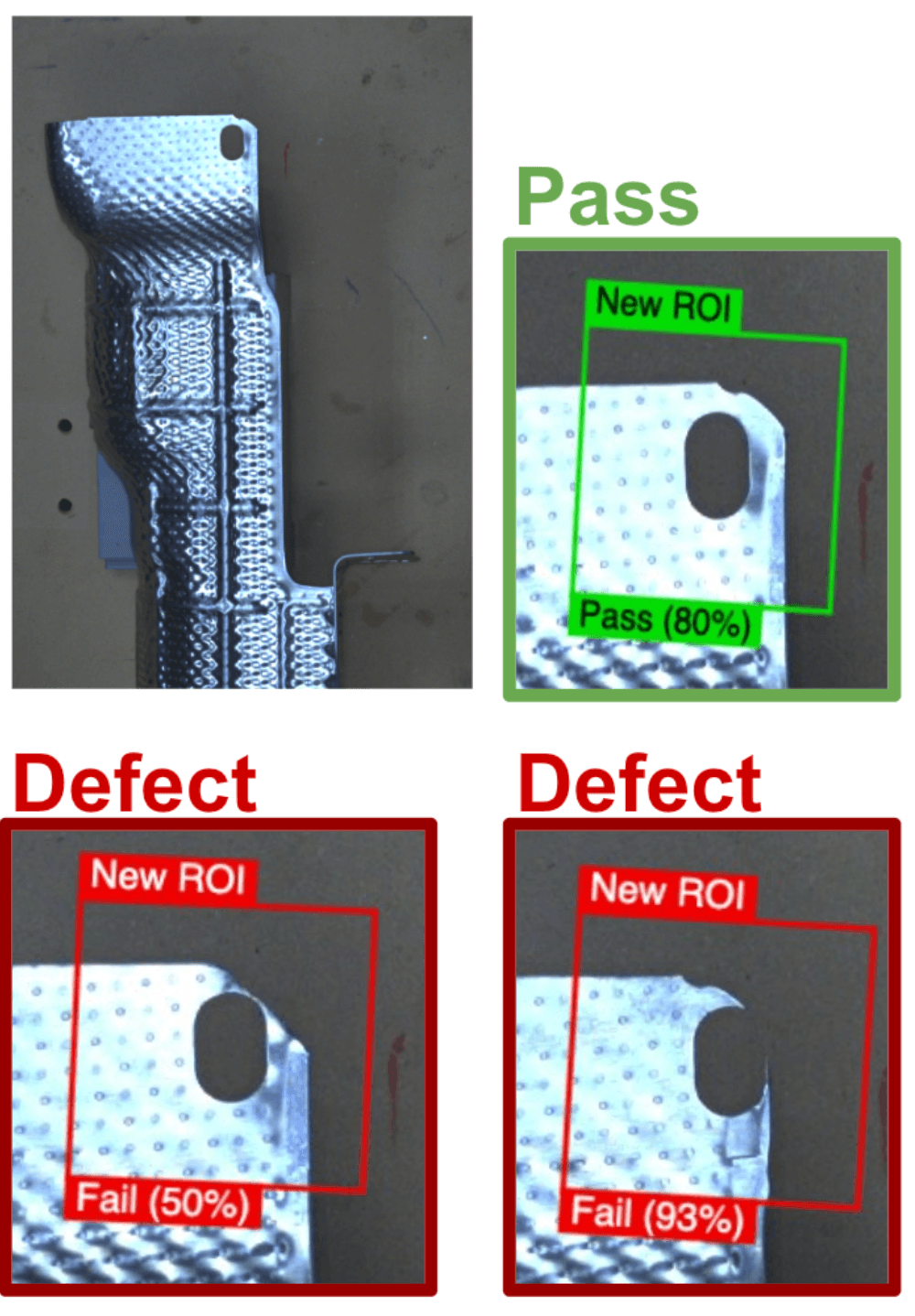

An aerospace supplier couldn't detect micro-fractures on reflective stamped parts. Using the OV20i Vision System in **photometric mode**, they eliminated glare and trained an AI classifier on just 20 images. The setup took under 20 minutes and achieved state-of-the-art accuracy.

The Challenge: Seeing Invisible Flaws on Mirrored Surfaces

Edge inspections on stamped metal parts are notoriously difficult. For an aerospace parts supplier, the task was to detect not just missing holes, but minor, micron-scale burrs and micro-fractures around hole edges. These tiny defects can compromise part integrity, but they are almost impossible to see with standard automated optical inspection (AOI).

The core problems were physics-based:

- Reflective Surfaces: Stamped metal acts like a mirror, creating intense glare that washes out the fine details of the edge.

- Inconsistent Lighting: Normal fluctuations in factory lighting would constantly shift the glare, making rule-based AOI systems unreliable.

Their existing cameras could confirm a hole was present, but missed the critical micro-defects, forcing slow and inconsistent manual checks.

Solution: Adaptive Illumination Meets Lean AI

The entire solution was built on the OV20i by leveraging one key feature: **photometric mode**.

Photometric Mode to Tame Glare

Instead of fighting reflections, the OV20i's photometric mode automatically adjusted the system's illumination and focus. It actively neutralized glare and shadowing, creating a clear, stable, and high-contrast image of the hole edge every single time, regardless of the part's finish.

A Hyper-Efficient Classifier Model

With the lighting problem solved, the AI didn't need a huge dataset. Engineers trained a simple **classifier model** on just **20 total images**. The setup, from unboxing to a fully accurate model, took less than **20 minutes**.

Key Engineering Takeaway

Adaptive illumination is the unsung hero of AI inspection. When lighting is consistent, AI models stay lean — and accurate.

FAQ

Why is it hard to inspect the edges of stamped metal parts?

Edge inspections on stamped metal are difficult because the parts are highly reflective, which creates glare. Inconsistent factory lighting and the microscopic size of defects like burrs and micro-fractures cause traditional AOI systems to fail.

What is photometric mode in an AI vision system?

Photometric mode is an advanced feature that automatically adjusts illumination and camera focus to create a consistent, optimized image. It actively eliminates glare and shadowing, which is critical for reliable inspection on mirrored or reflective surfaces.

How does adaptive illumination help AI models?

When the lighting is consistent and optimized, the AI model doesn't have to waste capacity learning to ignore glare or shadows. This allows it to be trained on a much smaller dataset (as few as 20 images) and focus entirely on identifying true defects, leading to higher accuracy.

Stop Fighting Glare on Reflective Parts

Discover how photometric AI can solve your toughest inspection challenges on stamped and machined metal.