The Challenge: Micron-Scale Defects and Mirror-Bright Surfaces

Medical device manufacturing demands perfection at microscopic scales. Even the slightest surface defect — a scratch, burr, or texture variation — can compromise biocompatibility, sterilization, or component performance.

In particular, small, reflective metal components like 1 mm-wide surgical rings and connectors present a perfect storm for inspection challenges:

- Mirror-like surfaces cause glare and reflections that overwhelm standard cameras

- Sub-millimeter scratches often disappear depending on viewing angle or lighting polarization

- Manual inspection under microscopes is slow (10+ seconds per ring), fatiguing, and inconsistent

- Training new operators to recognize borderline defects can take weeks or months

These limitations make traditional rule-based vision and human inspection unsustainable for modern throughput and regulatory demands.

Step 1: Get the Optics and Lighting Right

No AI model can learn what it can't see. For highly reflective surfaces, lighting geometry and magnification are decisive.

Overview AI's engineers deployed the OV80i Vision System with a 100 mm high-magnification telecentric lens paired with coaxial (on-axis) lighting.

This setup eliminated glare by directing light along the same optical axis as the camera sensor. The result was:

- ✓Microscope-level clarity across the 1 mm field of view

- ✓Uniform illumination without hot spots

- ✓Clear visualization of micro-scratches, pits, and roughness that were invisible to conventional side lighting

Because the OV80i's C-mount supports flexible lens swaps, engineers can tailor the field of view and working distance to each device geometry — from catheter hubs to orthopedic fasteners.

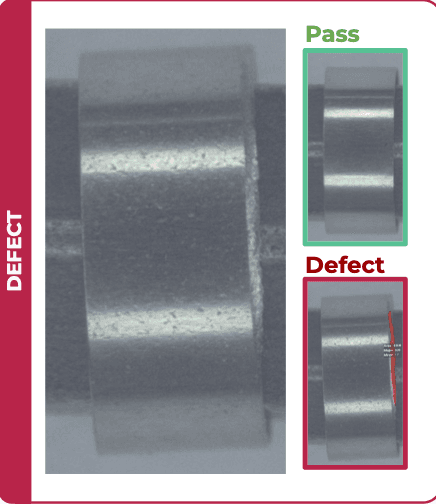

Step 2: Use AI Segmentation, Not Just Classification

While classifiers can flag a "good vs bad" part, segmentation goes a step further — it pinpoints exact defect pixels within the image.

This approach provides:

- Quantitative measurement of scratch length or area

- Pass/fail thresholds based on objective geometry rather than human judgment

- Visual overlays that help operators instantly verify defects

With the OV80i's web-based interface, engineers trained and labeled segmentation data directly in a browser — no extra software or scripting required.

Step 3: Rapid Training and Deployment

Using just 10 training images, Overview AI's team trained a segmentation recipe that achieved:

This eliminated the need for microscope checks and cut inspection time per part by an order of magnitude.

“Before, inspection was slow, tiring, and inconsistent. The OV80i gave us microscope-level clarity without glare and inspects orders of magnitude faster than our human inspectors.”

— Plant Manager, Medical Device Manufacturer

Step 4: Connecting to Production

The OV80i integrates easily into regulated manufacturing lines. Using Ethernet/IP or PROFINET, the system connects directly to PLCs and MES layers. Digital I/O provides triggers, reject outputs, and inspection status flags.

Recipes can be cloned, exported, and updated as product lines evolve — supporting continuous validation in compliance with FDA 21 CFR Part 11 or ISO 13485 record-keeping requirements.

The Result: Microscope-Level Inspection, Factory-Level Speed

| Metric | Result |

|---|---|

| Component | 1 mm Surgical Ring |

| Lens / Lighting | 100 mm Telecentric + Coaxial Light |

| Training Images | 10 |

| Time to Train | < 3 Hours |

| Accuracy | 100% (n = 40) |

This combination of precision optics, AI segmentation, and browser-based deployment proves that even reflective, micro-scale parts can achieve zero-miss inspection — without the overhead of traditional vision development.

Broader Implications

Micro-defect detection in medical devices isn't just about quality; it's about compliance and patient safety. As components shrink, automated optical inspection (AOI) powered by AI is becoming essential for:

✓ Surgical tools and orthopedic fasteners

✓ Medical imaging components

✓ Catheter tips and micro-connectors

✓ Dental and ophthalmic instruments

By reducing inspection subjectivity and training time, manufacturers can scale output while maintaining traceable, repeatable quality data.

FAQ: Microscale Inspection and AI Vision

Q: What lighting geometry works best for reflective metal parts?

A: Coaxial (on-axis) illumination minimizes glare by aligning light with the camera axis. For rougher surfaces, ring lighting or dark-field illumination can complement the setup.

Q: How small can defects be detected with the OV80i?

A: The system can detect defects smaller than 0.1% of the field of view, depending on lens magnification and working distance.

Q: How many training images are typically needed?

A: Many applications reach production accuracy with 5–15 images per defect type, leveraging transfer learning and segmentation recipes.

Q: Can this setup inspect other materials (polymers, glass)?

A: Yes — the OV80i's lighting and optics can be tuned for transparent or semi-reflective surfaces using cross-polarized or diffuse dome illumination.

Q: How does this compare to microscope inspection?

A: The AI system delivers comparable resolution but automates defect detection, enabling continuous, high-throughput inspection with consistent results.

The Takeaway

Microscale inspection doesn't have to mean slow, manual, and inconsistent. With the right combination of telecentric optics, on-axis lighting, and AI segmentation, manufacturers can achieve microscope-level precision — directly on the production floor.

Ready to solve your surface inspection challenges?

Learn more about AI-powered surface inspection with OV80i or contact us to discuss your application.