How AI Vision Simplifies Multi-Point Inspection for Complex Assemblies

Inspect castles, pins, clips, and inserts in a single, stable shot with AI-powered vision.

TL;DR (Quick Answer)

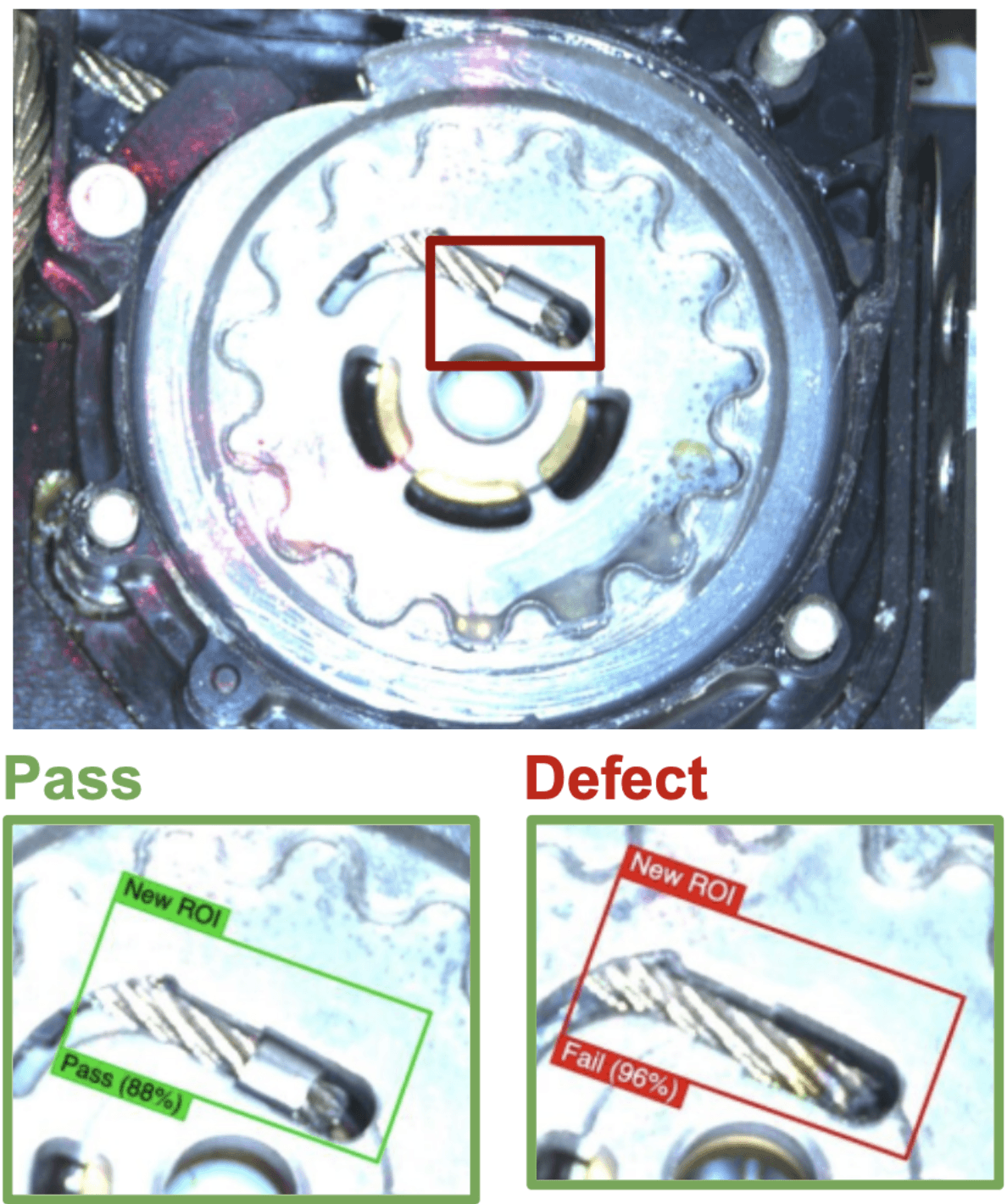

An automotive supplier struggled to inspect four different components on a winch assembly at once. Using the OV20i Vision System, they trained a model on just 5-6 images per defect to achieve stable, multi-point inspection—even on low-contrast parts—eliminating the need for recalibration.

The Challenge: One Assembly, Four Critical Checks

Inspecting a single part is relatively easy; inspecting four unique subassemblies simultaneously isn’t. A global automotive supplier needed to reliably inspect complex winch assemblies, verifying the correct state of a castle, pin, spring clip, and inserts all in one view.

Why Conventional Vision Fails

The supplier’s existing machine vision system was a source of constant frustration and production delays. It struggled with several key issues:

- Inability to Generalize: The system couldn't detect all defects simultaneously across four different component types.

- Low-Contrast Surfaces: It failed to reliably distinguish silver-on-silver components, like a pin against a metal housing, leading to false negatives.

- Constant Recalibration: Minor changes in ambient lighting or part orientation required frequent, time-consuming manual recalibration by an operator.

- Vague Feedback: When a failure was detected, it often gave a generic "NG" (No-Go) signal, forcing operators to manually investigate which of the four components was faulty.

The Overview.ai Solution: One Camera, One Model

Using the OV20i industrial vision system, engineers deployed a single camera and trained one comprehensive AI model to handle all four inspection points.

Fast Training on Minimal Data

Engineers trained the model on just 5–6 images per defect type. Because the optics and lighting were stable, the AI quickly learned to identify all critical failure modes without needing thousands of examples.

Robust Low-Contrast Detection

The OV20i's high-quality sensor and processing capabilities allowed it to reliably identify features on challenging silver-on-silver low-contrast surfaces, a task where the previous system consistently failed.

Defect-Specific Alerts with Node-RED

Custom Node-RED logic was used to interpret the model's output. Instead of a generic fail signal, the system delivered defect-specific alerts to the PLC and HMI, telling operators exactly which feature (e.g., "Clip Missing" or "Pin Misaligned") required correction.

Results and Key Insight

The implementation led to immediate and significant process improvements:

- Stable detection across all component variations and lighting conditions.

- Total elimination of manual recalibration cycles, freeing up operator time.

- A sharp reduction in false rejects and a more efficient operator workflow.

Reliable AI inspection isn’t about large datasets — it’s about repeatable optics, consistent illumination, and transparent feedback loops.

FAQ

What makes multi-point inspection difficult for traditional cameras?

Traditional systems struggle to detect multiple, unique defects at once, especially on low-contrast surfaces (e.g., silver-on-silver). They often require constant recalibration to handle normal variations in lighting and component orientation.

How does AI vision solve this inspection challenge?

AI models, like those on the OV20i, can be trained to recognize multiple component features and defects in a single view. They are robust to lighting variations and can identify subtle issues on low-contrast parts without recalibration.

How much data is needed for a complex multi-point inspection?

It is more about image quality than quantity. With stable optics and lighting, an effective AI model can be trained on a small dataset, sometimes as few as 5-6 images per defect type.

Ready to Stabilize Your Complex Assembly Inspection?

Get started with the OV20i AI Vision System for reliable, high-speed multi-point quality control.