Detecting "Soft-Set" Conditions in Press-/Interference-Fit Assemblies: Why It's Hard—and How AI Classifiers Help

A "soft-set" occurs when an interference/press-fit joint isn't fully seated—it looks close, sometimes passes a casual glance, but lacks the designed interference and mechanical engagement. In automotive drivelines (e.g., half-shafts), steering, hubs, or couplers, soft-set conditions can propagate into NVH, wear, or failure under load.

The Real Problem (And Why It Keeps Biting Teams)

Three technical realities make automated detection tricky:

1. Micron-Scale Fit Differences

Press-/interference fits rely on tight tolerances, material elasticity, and surface finish. The visual delta between "fully seated" and "almost" can be millimetric—or smaller and partly hidden.

2. Inaccessibility + Occlusion

The joint is buried inside assemblies; camera viewpoints are constrained; lighting is inconsistent.

3. Pose and Perspective

Small angle changes alter apparent gaps; a few degrees of tilt can mask the very cue you need unless you correct perspective or train across view variation.

Why Conventional Checks Miss Soft-Sets

- •Binary sensors (simple presence/height switches) can read "OK" even when seating is marginal.

- •Rule-based vision struggles when the feature of interest is partially occluded or only visible under a specific angle/light.

- •Manual inspection is slow and subjective—especially at line speed.

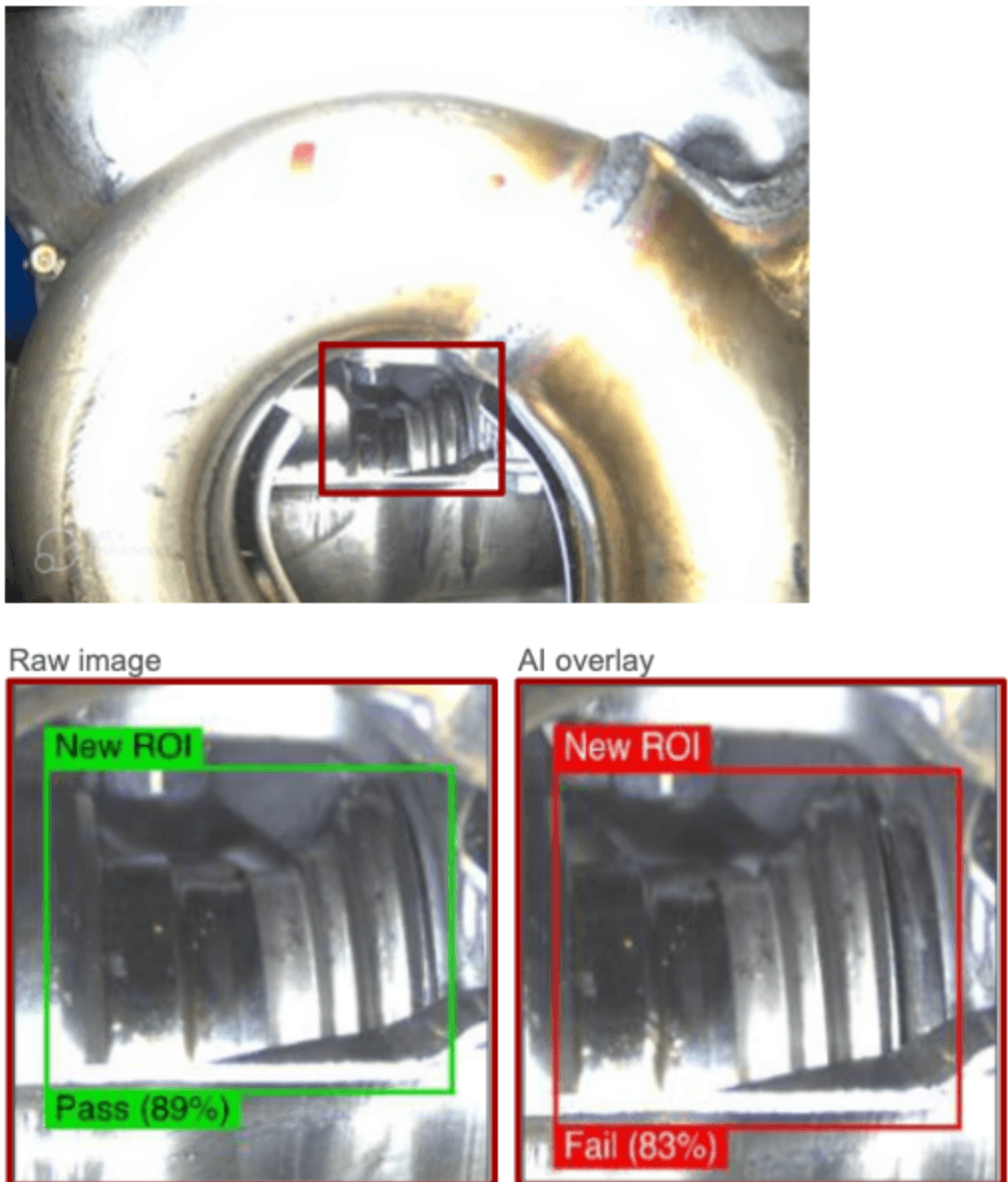

How Overview AI Solves It (Fast, Minimal Data, Production-Safe)

1. Teach a Classifier the Condition (Not the Pixels Alone)

We build a classifier recipe that learns "correctly seated" vs. "soft-set" from labeled images of your actual assembly. Because we're learning appearance of states, the model generalizes to minor finish/lighting shifts better than brittle rules.

2. Train at the Edge; Iterate in Hours

Using OV-series edge hardware (e.g., OV20i or OV80i), we train on-device (NVIDIA Xavier NX / Orin NX). Typical cycles:

- 1.capture a handful of examples (per state),

- 2.label in the browser,

- 3.train in ~15–60 minutes,

- 4.validate in shadow mode, then go live.

3. Add Light Logic to Minimize Overkill

Once live, we refine confidence thresholds and add light decision logic (e.g., voting across frames, region masks). That keeps false rejects low while preserving sensitivity.

4. Integrate to Your Line + Assurance Workflows

We output to PLCs (EtherNet/IP, PROFINET) and store image + decision logs, supporting fastener/fit assurance documentation and customer audits (your FAS).

What "Good" Looks Like

State-of-the-Art Accuracy

Distinguishing soft-set vs. fully seated in obstructed geometries.

Rapid Deployment

Hours, not weeks to production-ready inspection.

Low Overkill

Via tuned thresholds and temporal voting.

Traceable Artifacts

For PPAP/FAS: images, timestamps, recipe versioning.

FAQs

What exactly causes a soft-set?

Tolerance stack-ups, surface finish or lubricant effects, and misalignment during insertion can leave parts partially seated. Press-/interference-fit behavior is sensitive to both dimensional control and local surface condition.

We can barely see the joint—can vision still work?

Yes. We design views to expose small cues (shadow, shoulder alignment, ring visibility) and train the classifier to those cues. When perspective varies, we either correct it or include pose variation during training.

How many images do we need?

Start with a small, curated set (dozens) across both states; expand with edge cases as they appear. Edge training makes each iteration fast.

How do you avoid flagging good parts (overkill)?

We combine model confidence with guard-banded thresholds and per-cell voting logic, tuned under real production lighting.

Will this satisfy our FAS/traceability requirements?

Yes—stored images, overlays, and decision logs provide objective evidence aligned to Fastener Assurance System workflows and FQA/contractual needs.

Ready to Eliminate Soft-Set Defects?

Explore our edge AI vision systems and discover how fast you can deploy soft-set detection.